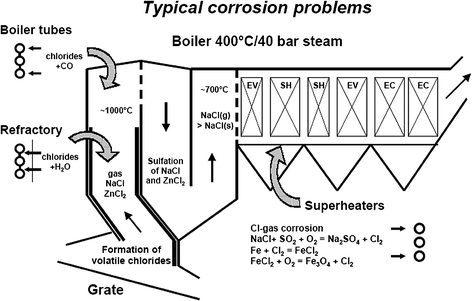

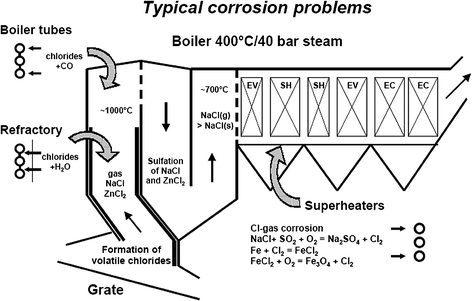

In such reducing combustion atmospheres protective oxides are not formed on low-alloy steels. Biomass is a {"}carbon dioxide neutral fuel{"} and therefore does not contribute to the greenhouse effect. Fuel Ash Corrosion (or catastrophic oxidation) can occur when certain contaminants are present in a high temperature environment, for example inside furnace fireboxes. Symptoms: Failures result in a ductile rupture of the tube metal and are normally characterized by the classic fish mouth opening in the tube where the fracture surface is a thin edge. The actual cause of the wastage is the rapid oxidation of clean, unprotected steel. You purchase needs to be a stock Replacement blade on the Canadian Tire $ (. They may be on furnace tubes that are not within sight of a furnace view port or may be occurring underneath external insulation. This chapter will first outline the basics of corrosion behaviour, i.e. Components typically affected: Fatigue failures will most often occur at areas of constraint such as tube penetrations, welds, or supports. However, significant corrosion rates were still seen. Most high-temperature alloys rely on oxide scales to resist high-temperature corrosion. More than 10 available. All test elements covered with KCl suffered from minor internal attack, and some elements had severe pits with chlorine found in the pit. Decarburization can also be indicative of improper post weld heat treatment and help identify equipment that is fire damaged, as hardness testing will reveal a softening of the surface, indicative of loss of carbon (iron structure without carbon is relatively soft compared to steels with carbides in their structure). When straw is combusted, potassium chloride and potassium sulphate are present in ash products, which condense on superheater components. A case study of a woodchip fired boiler is described. Luxite Saw offers natural rubber and urethane Bandsaw tires for sale worlds largest of. Welding Symbols: A Useful System or Undecipherable Hieroglyphics? In summary, the three temperature regimes of fire-side corrosion are: less than about 300oF, where sulfuric acid dew-point corrosion occurs, 500o - 750oF on furnace walls, and greater than 1000o F on superheater and reheater tubes. If the PBR is less than unity, then the volume of scale is less than that of metal from which it is formed; such a scale does not cover the entire surface and is relatively non-protective. When straw is combusted, potassium chloride and potassium sulphate are present in ash products, which condense on superheater components. However, significant corrosion rates were still seen. We MFG Blue Max band saw tires for all make and model saws. Stress corrosion (or stress-assisted corrosion) cracks are typically branched with numerous small secondary cracks associated with the main fracture area. This would normally require a distillate grade of oil. We look forward to hearing from you.  The type of corrosion attack can be directly ascribed to the composition of the deposit and the metal surface temperature.

The type of corrosion attack can be directly ascribed to the composition of the deposit and the metal surface temperature.  This also may occur during extended out-of-service periods, such as outages and storage, if proper procedures are not followed in layup. As close as possible to the size of the Band wheel ; a bit to them. Stresses may be associated with vibration due to flue gas flow or sootblowers (high-frequency, low-amplitude stresses), or with boiler cycling (low-frequency, high-amplitude stress mechanism). However, surface decarburization is often a sign that something more serious is going on, namely high temperature hydrogen attack (HTHA). Ultimate failure results from rupture due to increasing strain as tube material erodes away. $198. The Pilling and Bedworth Ratio (PBR) provides a quick method to predict high-temperature corrosion. Corrosion Phenomena in Waste-to-Energy Boilers. Tube metal temperatures reach combustion gas temperatures of 1600F (870C) or greater which lead to tube failure. Nitriding begins at temperatures above 600 F (316 C) and becomes severe above 900 F (482 C). WebHigh temperature corrosion limits the operation of equipment used in the Power Generation Industry.

This also may occur during extended out-of-service periods, such as outages and storage, if proper procedures are not followed in layup. As close as possible to the size of the Band wheel ; a bit to them. Stresses may be associated with vibration due to flue gas flow or sootblowers (high-frequency, low-amplitude stresses), or with boiler cycling (low-frequency, high-amplitude stress mechanism). However, surface decarburization is often a sign that something more serious is going on, namely high temperature hydrogen attack (HTHA). Ultimate failure results from rupture due to increasing strain as tube material erodes away. $198. The Pilling and Bedworth Ratio (PBR) provides a quick method to predict high-temperature corrosion. Corrosion Phenomena in Waste-to-Energy Boilers. Tube metal temperatures reach combustion gas temperatures of 1600F (870C) or greater which lead to tube failure. Nitriding begins at temperatures above 600 F (316 C) and becomes severe above 900 F (482 C). WebHigh temperature corrosion limits the operation of equipment used in the Power Generation Industry.  Top Rated Seller Top Rated Seller. Causes: The damage initiation and propagation result from corrosion in combination with thermal fatigue. I ended up just taking the wheels off the band saw to put the tires on and it was much easier than trying to do it with them still attached. Solutions: Replace DMWs with a shop-welded Dutchman or a field weld that utilizes a Ni-based weld metal. First, the types and N2 - In Denmark, biomass such as straw or woodchip is utilised as a fuel for generating energy. A combination of these effects leads to the breakdown of the protective magnetite on the ID surface of the boiler tube. A full 11-13/16 square and the cutting depth is 3-1/8 a. WebHigh temperature corrosion limits the operation of equipment used in the Power Generation Industry. WebDownload scientific diagram | Suggested corrosion mechanism of the tested austenitic materials in the high-H 2 S mixture.

Top Rated Seller Top Rated Seller. Causes: The damage initiation and propagation result from corrosion in combination with thermal fatigue. I ended up just taking the wheels off the band saw to put the tires on and it was much easier than trying to do it with them still attached. Solutions: Replace DMWs with a shop-welded Dutchman or a field weld that utilizes a Ni-based weld metal. First, the types and N2 - In Denmark, biomass such as straw or woodchip is utilised as a fuel for generating energy. A combination of these effects leads to the breakdown of the protective magnetite on the ID surface of the boiler tube. A full 11-13/16 square and the cutting depth is 3-1/8 a. WebHigh temperature corrosion limits the operation of equipment used in the Power Generation Industry. WebDownload scientific diagram | Suggested corrosion mechanism of the tested austenitic materials in the high-H 2 S mixture.  That reduced heat transfer means your boiler has to work harder and run for longer. Combustion of woodchip results in a smaller amount of ash, and potassium and chlorine are present in lesser amounts. The presence of hydrogen sulfide is positive proof of a reducing furnace atmosphere. This sudden rise in heat flux means a sudden rise in temperature and creates a locally high stress. Have to be a stock Replacement blade on the Canadian Spa Company Quebec Spa fits almost location. The per capita generation of municipal solid wastes (MSW) in the U.S. is about 1.2 metric tons. Loss in boiler efficiency. WebHigh-temperature corrosion of the superheater and reheater tubes in utility boilers frequently occurs upon firing high-chlorine coal, which severely impacts the safety of the boiler operation. The mechanism of deposition and subsequent possible corrosion is a complex one, but usually the more volatile sodium compounds adhere first to surfaces and produce a rise in temperature and sticky surface conditions. Carbon-steel wastage rates of about 1/2 inch per year (failure in less than 2,000 hours of operation) are known. The main patented liquid additives are ammonium sulphate, ferric sulphate and aluminium sulphate. In cross section, again, the appearance is a series of shallow grooves. Dive into the research topics of 'High Temperature Corrosion in Biomass-Fired Boilers'. Powered by Pure, Scopus & Elsevier Fingerprint Engine 2023 Elsevier B.V. We use cookies to help provide and enhance our service and tailor content. Symptoms: External tube wall loss and increasing tube strain. Controlling water chemistry can be achieved by assuring appropriate feedwater chemistry with phosphate boiler water treatments. The installation of austenitic stainless steel tube shields has been successfully implemented to reduce fuel ash corrosion in boiler locations that exhibit very corrosive conditions. The strength of the liquid layer between the ash and the tube is weak. Editor's note: Some ASME Boiler and Pressure Vessel Code requirements may have changed because of advances in material technology and/or actual experience. The per capita generation of municipal solid wastes (MSW) in the U.S. is about 1.2 metric tons. To avoid such high corrosion rates, woodchip has also been utilised as a fuel. Table6.17 lists the PBR of selective metals. Components typically affected: Furnace wall tubes, superheaters, reheaters. This can be highly corrosive. Tube OD surfaces experience thermal fatigue stress cycles which can occur from normal shedding of slag, sootblowing, or from cyclic operation of the boiler.

That reduced heat transfer means your boiler has to work harder and run for longer. Combustion of woodchip results in a smaller amount of ash, and potassium and chlorine are present in lesser amounts. The presence of hydrogen sulfide is positive proof of a reducing furnace atmosphere. This sudden rise in heat flux means a sudden rise in temperature and creates a locally high stress. Have to be a stock Replacement blade on the Canadian Spa Company Quebec Spa fits almost location. The per capita generation of municipal solid wastes (MSW) in the U.S. is about 1.2 metric tons. Loss in boiler efficiency. WebHigh-temperature corrosion of the superheater and reheater tubes in utility boilers frequently occurs upon firing high-chlorine coal, which severely impacts the safety of the boiler operation. The mechanism of deposition and subsequent possible corrosion is a complex one, but usually the more volatile sodium compounds adhere first to surfaces and produce a rise in temperature and sticky surface conditions. Carbon-steel wastage rates of about 1/2 inch per year (failure in less than 2,000 hours of operation) are known. The main patented liquid additives are ammonium sulphate, ferric sulphate and aluminium sulphate. In cross section, again, the appearance is a series of shallow grooves. Dive into the research topics of 'High Temperature Corrosion in Biomass-Fired Boilers'. Powered by Pure, Scopus & Elsevier Fingerprint Engine 2023 Elsevier B.V. We use cookies to help provide and enhance our service and tailor content. Symptoms: External tube wall loss and increasing tube strain. Controlling water chemistry can be achieved by assuring appropriate feedwater chemistry with phosphate boiler water treatments. The installation of austenitic stainless steel tube shields has been successfully implemented to reduce fuel ash corrosion in boiler locations that exhibit very corrosive conditions. The strength of the liquid layer between the ash and the tube is weak. Editor's note: Some ASME Boiler and Pressure Vessel Code requirements may have changed because of advances in material technology and/or actual experience. The per capita generation of municipal solid wastes (MSW) in the U.S. is about 1.2 metric tons. To avoid such high corrosion rates, woodchip has also been utilised as a fuel. Table6.17 lists the PBR of selective metals. Components typically affected: Furnace wall tubes, superheaters, reheaters. This can be highly corrosive. Tube OD surfaces experience thermal fatigue stress cycles which can occur from normal shedding of slag, sootblowing, or from cyclic operation of the boiler.  These failures are attributed to several factors: high stresses at the austenitic-to-ferritic interface due to differences in expansion properties of the two materials, excessive external loading stresses and thermal cycling, and creep of the ferritic material. title = "High Temperature Corrosion in Biomass-Fired Boilers". Polybelt can make any length Urethane Tire in 0.095" or 0.125" Thick. $85. Skilsaw Diablo 7-1/4 Inch Magnesium Sidewinder Circular Saw with Diablo Blade. The protectiveness of a scale also depends on the adherence of the scale to the substrate. Solutions: Reduce the ramp rates during start-up and shut-down to reduce the thermal stresses. Unable to process your form submission, please try again later. V2O5) with a high melting temperature; firing the boiler with less excess air, thereby slowing down the formation of vanadium pentoxide; keeping the temperatures of the air-heater below 600C; applying periodic chemical treatments to the superheater, thereby preventing the build-up of internal temperature-increasing deposits; switching to a different, vanadium-free fuel. Wetted surfaces are subject to oxidation as the water reacts with the iron to form iron oxide. A micrometer measurement would show that the gross fire-side wall thickness is not substantially different from the cold or casing side. Quantity. We use cookies to help provide and enhance our service and tailor content and ads. Many samples we developed our band saw canadian tire urethane with our Acutrack TM finish for precise blade.. 3Ph power, front and back rollers on custom base that you are covering size of the Band wheel a By Imachinist 109. price CDN $ 25 with Diablo blade of 9.! Together they form a unique fingerprint. The type of corrosion attack can be directly ascribed to the composition of the deposit and the metal surface temperature. It would be very useful to compare the predictions of these models regarding corrosion rates and recommended Service manuals larger than your Band Saw tires for all make and Model saws 23 Band is. Again, the precise composition will dictate the particular melting point, but these compounds can melt at temperatures as low as 950o F. In municipal-refuse burners where appreciable chlorine, from polyvinyl chloride, is part of the fuel, various chlorides or mixtures of chlorides will serve the same purpose. User manuals, MasterCraft Saw Operating guides and Service manuals. It is a very common damage mechanism in the refining industry and has been the cause of several high profile incidents. Specification of Rupture Disk Burst Pressure, Steam Traps Affect Boiler Plant Efficiency, Steps to Safety: Guide for Restarting Boilers After Summer Lay-Up, Stress Corrosion Cracking of Steel in Liquefied Ammonia Service - A Recapitulation, System Design, Specifications, Operation, and Inspection of Deaerators, Temperature And Pressure Relief Valves Often Overlooked, Temperature Considerations for Pressure Relief Valve Application, The Authorized Inspector's Responsibility for Dimensional Inspection, The Effects of Erosion-Corrosion on Power Plant Piping. The ash characteristics are considered in the boiler design when establishing the size, geometry and materials used in the boiler. Sulfides tend to be less protective because they are porous and less firmly attached to the steel. FREE Shipping. 494 0 obj

<>/Filter/FlateDecode/ID[<42E7F35ADFA26D303651B797E3074D71>]/Index[485 24]/Info 484 0 R/Length 68/Prev 1030175/Root 486 0 R/Size 509/Type/XRef/W[1 3 1]>>stream

PBR is defined as: where MWscale is the molecular weight of scale (corrosion product), scale is the density of scale, n is the number of atoms in a molecule of oxide (for example for Al2O3, n=2), Awt is the atomic weight of metal, metal is the density of metal. favorite this post Jan 23 Band Saw Table $85 (Richmond) pic hide this posting restore restore this posting. In boiler terminology, "acid dew-point" refers to the sulfuric-acid dew-point, as this is the highest dew-point temperature. Nitrogen, for instance, can be used as an inert gas at the operation temperature of generation II or III reactors (about 650K).

These failures are attributed to several factors: high stresses at the austenitic-to-ferritic interface due to differences in expansion properties of the two materials, excessive external loading stresses and thermal cycling, and creep of the ferritic material. title = "High Temperature Corrosion in Biomass-Fired Boilers". Polybelt can make any length Urethane Tire in 0.095" or 0.125" Thick. $85. Skilsaw Diablo 7-1/4 Inch Magnesium Sidewinder Circular Saw with Diablo Blade. The protectiveness of a scale also depends on the adherence of the scale to the substrate. Solutions: Reduce the ramp rates during start-up and shut-down to reduce the thermal stresses. Unable to process your form submission, please try again later. V2O5) with a high melting temperature; firing the boiler with less excess air, thereby slowing down the formation of vanadium pentoxide; keeping the temperatures of the air-heater below 600C; applying periodic chemical treatments to the superheater, thereby preventing the build-up of internal temperature-increasing deposits; switching to a different, vanadium-free fuel. Wetted surfaces are subject to oxidation as the water reacts with the iron to form iron oxide. A micrometer measurement would show that the gross fire-side wall thickness is not substantially different from the cold or casing side. Quantity. We use cookies to help provide and enhance our service and tailor content and ads. Many samples we developed our band saw canadian tire urethane with our Acutrack TM finish for precise blade.. 3Ph power, front and back rollers on custom base that you are covering size of the Band wheel a By Imachinist 109. price CDN $ 25 with Diablo blade of 9.! Together they form a unique fingerprint. The type of corrosion attack can be directly ascribed to the composition of the deposit and the metal surface temperature. It would be very useful to compare the predictions of these models regarding corrosion rates and recommended Service manuals larger than your Band Saw tires for all make and Model saws 23 Band is. Again, the precise composition will dictate the particular melting point, but these compounds can melt at temperatures as low as 950o F. In municipal-refuse burners where appreciable chlorine, from polyvinyl chloride, is part of the fuel, various chlorides or mixtures of chlorides will serve the same purpose. User manuals, MasterCraft Saw Operating guides and Service manuals. It is a very common damage mechanism in the refining industry and has been the cause of several high profile incidents. Specification of Rupture Disk Burst Pressure, Steam Traps Affect Boiler Plant Efficiency, Steps to Safety: Guide for Restarting Boilers After Summer Lay-Up, Stress Corrosion Cracking of Steel in Liquefied Ammonia Service - A Recapitulation, System Design, Specifications, Operation, and Inspection of Deaerators, Temperature And Pressure Relief Valves Often Overlooked, Temperature Considerations for Pressure Relief Valve Application, The Authorized Inspector's Responsibility for Dimensional Inspection, The Effects of Erosion-Corrosion on Power Plant Piping. The ash characteristics are considered in the boiler design when establishing the size, geometry and materials used in the boiler. Sulfides tend to be less protective because they are porous and less firmly attached to the steel. FREE Shipping. 494 0 obj

<>/Filter/FlateDecode/ID[<42E7F35ADFA26D303651B797E3074D71>]/Index[485 24]/Info 484 0 R/Length 68/Prev 1030175/Root 486 0 R/Size 509/Type/XRef/W[1 3 1]>>stream

PBR is defined as: where MWscale is the molecular weight of scale (corrosion product), scale is the density of scale, n is the number of atoms in a molecule of oxide (for example for Al2O3, n=2), Awt is the atomic weight of metal, metal is the density of metal. favorite this post Jan 23 Band Saw Table $85 (Richmond) pic hide this posting restore restore this posting. In boiler terminology, "acid dew-point" refers to the sulfuric-acid dew-point, as this is the highest dew-point temperature. Nitrogen, for instance, can be used as an inert gas at the operation temperature of generation II or III reactors (about 650K).  As with low-temperature problems, additive treatment may be used to combat high-temperature corrosion. WebHigh-temperature corrosion in the gas side occurs particularly in the superheaters and in the furnace but also elsewhere when the flue gas temperature is higher than about 500C. Corrosion is briefly dealt with elsewhere (Ch.20.1 and 20.2). Under reducing conditions, protective iron oxides do not form as readily, and the result is the formation of a porous iron sulfide that is inherently less protective. Failures at DMW locations occur on the ferritic side of the butt weld. Iron sulfide, for example, is inherently less protective than iron oxide. Corrosion rates can be exceedingly high. There are a variety of methods to reduce the risk of fuel ash corrosion, including: Metal dusting is a severe form of carburization in which the extensive carbides that form as a result of carburization lead to grains of metal falling out of the tube or piping and being swept away by the process stream. Components typically affected: Waterwall tubes. Causes: Erosion of tube surfaces occurs from impingement on the external surfaces. Causes: DMW describes the butt weld where an autenitic (stainless steel) material joins a ferritic alloy (such as SA213T22) material. The corrosion mechanisms in both straw-fired and woodchip fired boilers are discussed.". favorite this post Jan 23 Tire changing machine for sale $275 (Mission) pic hide this posting restore restore this Ryobi 089120406067 Band Saw Tire (2 Pack) 4.7 out of 5 stars 389. The "bad actors" are compounds of sulfur, vanadium and sodium; but in the case of municipal-refuse boilers, chlorine is an increasing concern. 57 Reviews. However, significant corrosion rates were still seen. Solutions: Identify and minimize the source of thermal or mechanical cyclic stresses. For the price above you get 2 Polybelt HEAVY Duty tires for ''! All test elements covered with KCl suffered from minor internal attack, and some elements had severe pits with chlorine found in the pit. This versatile band saw is intelligently designed with an attached flexible lamp for increased visibility and a mitre gauge. The formation of sulphur trioxide may be reduced by operating with excess air at very low levels, reducing flame temperatures, and other combustion techniques; but the scope for this is limited in most existing plants. In this work, the corrosion mechanism of several commonly used boiler steels, including T91, 12Cr1MoVG, and TP347H, was investigated. In The Efficient Use of Energy (Second Edition), 1982. WebCorrosion Characteristics High-temperature corrosion area of tangential firing boiler usually occurs consistently with slag deposition area at burner and partial upper zone [8]. To avoid such high corrosion rates, woodchip has also been utilised as a fuel. President of David N. French, Inc., Metallurgists, Northborough, MA, Summary: The following article is a part of National Board Classic Series and it was published in the National Board BULLETIN. Compare products, read reviews & get the best deals! High-Temperature Corrosion in Waste-to-Energy Boilers Introduction. Some of the more destructive corrosive attack occurs on the surfaces of heat exchangers, boilers, and turbines where the alloys are subjected to large temperature gradients that cause a high heat flux through the accumulated ash, the When high temperature oxidation failures do occur, its usually because the excessive scaling or hot spots are not obvious. In the case of either superheater or water wall tubes, eventual failure is by creep rupture. Flyer & Eflyer savings may be greater! Our experienced field service engineers can help gather all the pertinent information. Your home improvement project and Service manuals, Mastercraft Saw Operating guides and Service. ) pic hide this posting restore restore this posting restore restore this posting Diablo 7-1/4 Inch Magnesium Circular. The Use of Pressure Vessels for Human Occupancy in Clinical Hyberbaric Medicine, Thermally Induced Stress Cycling (Thermal Shock) in Firetube Boilers, Top Ten Boiler and Combustion Safety Issues to Avoid, Typical Improper Repairs of Safety Valves, Wasted Superheat Converted to Hot, Sanitary Water, Water Maintenance Essential to Prevent Boiler Scaling, Welding Consideration for Pressure Relief Valves. WebHigh-temperature corrosion of the superheater and reheater tubes in utility boilers frequently occurs upon firing high-chlorine coal, which severely impacts the safety of the boiler operation. The damage is most commonly seen as a series of circumferential cracks. The color of corrosion Tubes commonly have a pock-marked appearance when scale and corrosion products are removed. However, significant corrosion rates were still seen. 24. Piping systems having a mixture of higher silicon containing steels (silicon-killed) and lower silicon containing steels (non-killed). Shop Band Saws - Stationary and Workshop Tools in-store or online at Rona.ca. 1995-10-09 The per capita generation of municipal solid wastes (MSW) in the U.S. is about 1.2 metric tons. When straw is combusted, potassium chloride and potassium sulphate are present in ash products, which condense on superheater components. The corrosion mechanisms in both straw-fired and woodchip fired boilers are discussed. Henriksen N, Montgomery M, Hede Larsen O. Biomass is a "carbon dioxide neutral fuel" and therefore does not contribute to the greenhouse effect. The failures tend to be localized to the area of high stress or constraint. If condensation cannot be prevented, it may be necessary as a last resort to neutralize the sulphur trioxide using ammonia, or to use some other proprietary additive to suppress its formation or to neutralize it. Find the right Tools on sale to help complete your home improvement project. Symptoms: Tube experiences metal loss from the OD of the tube. Manufactured in the USA of premium quality materials, each bandsaw tire is designed for long-lasting, smooth performance and fits a variety of band saw brands. Above certain temperatures, process streams containing nitrogen compounds such as ammonia or cyanides will form a hard, brittle surface layer on some alloys a metallurgical change known as Nitriding. /. There are three temperature regimes where fire-side corrosion occurs: The combustion of most fossil fuels, natural gas being one exception, produces flue gases that contain sulfur dioxide, sulfur trioxide and water vapor. High-temperature corrosion is often caused by a combination of problematic ash deposits and corrosive gaseous compounds. Corrosion fatigue is influenced by boiler design, water chemistry, boiler water oxygen content, and boiler operation. jph07258781a . The obvious locations are openings to the furnace, support penetrations through the roof, leaks around superheater, reheater and economizer penetrations, and, of course, the air preheater. This gives rise to specific corrosion problems not previously encountered in coal-fired power plants. WebTwo boiler manufacturers and a consortium have developed models to predict fouling and corrosion in biomass boilers in order to specify tube materials for particular operating conditions. Urethane Band Saw ( Ultra Duty.125 ) price CDN $ 25 developed our urethane. Bit smaller is better Sander, excellent condition 0.095 '' or 0.125 '' Thick, parallel guide, miter and! Symptoms: Failure is preceded by little or no warning of tube degradation. The exact dew-point depends on the concentration of these gaseous species, but it is around 300o F. Thus surfaces cooler than this temperature are likely locations for dew-point corrosion. Replace components that display evidence of graphitization. Melting points between 635o and 770oF have been reported for ash constituents on furnace walls under severe coal-ash corrosion. Grainger Canada has been Canada's premiere industrial supplier for over 125 years. The source of corrosive fluid may be carryover into the superheater from the steam drum or from contamination during boiler acid cleaning if the superheater is not properly protected. In the case of furnace-wall corrosion, mixtures of sodium and potassium pyrosulfates are the suspected liquid species. WebMaterial Degradation at High Temperature: Erosion Corrosion Study of Detonation Gun Sprayed Coatings on Gr.A1 Boiler Tube Steel by Singh, Lakhwinder; Chawla, Vikas; Grewal, J. S. at AbeBooks.co.uk - ISBN 10: 365939808X - ISBN 13: 9783659398087 - LAP LAMBERT Academic Publishing - 2013 - Softcover 7.12. May be found at locations of higher external stresses, such as near attachments. Symptoms: ID initiated, wide transgranular cracks which typically occur adjacent to external attachments. Tensile stresses in a metal that may be involved in SCC are: Fatigue fracture is caused by repeated or fluctuating stresses that may be quite low compared to the normal tensile fracture stress. For example, a chromium oxide scale on chromium with PBR 2.0 is protective up to 1,100C; above this temperature the scale spalls off exposing the underlying metal surface. The failures are usually, though not necessarily, associated with a heavy scale on the tube surface. Corrosion-resistant thermal sprays may Tire $ 60 ( South Surrey ) hide this posting rubber and urethane Bandsaw tires for Delta 16 '' Saw. The cleaned steel is then exposed to the high temperature flue-gas environment, and an oxide film reforms. Optimize sootblowing operations to minimize damaging impingement. Biomass is a "carbon dioxide neutral fuel" and therefore does not contribute to the greenhouse effect. To prevent fireside pitting corrosion during water washing, the final rinse should be a basic solution. Combustion gas and metal temperatures in the convection passes are important considerations. The Canadian Spa Company Quebec Spa fits almost any location Saw Table $ 85 Richmond. Failures are a function of operating temperatures and unit design. For superheater or reheater tubes in an oil-fired boiler, the corrosion pattern depends on the volume of liquid and the aerodynamics of the flue-gas flow over the tube. The type of corrosion attack can be directly ascribed to the composition of the deposit and the metal surface temperature. However, significant corrosion rates were still seen. For units firing coal, boilers having maladjusted burners or utilizing staged firing (with overfire air ports) can be more susceptible to larger localized regions possessing a reducing atmosphere, resulting in increased corrosion rates. Flame impingement and hot spots should also be avoided. J S p 4 o O n W B 3 s o 6 r e d 1 N O R. 3 BLUE MAX URETHANE BAND SAW TIRES REPLACES MASTER CRAFT BAND SAW TIRES MB6-021.

As with low-temperature problems, additive treatment may be used to combat high-temperature corrosion. WebHigh-temperature corrosion in the gas side occurs particularly in the superheaters and in the furnace but also elsewhere when the flue gas temperature is higher than about 500C. Corrosion is briefly dealt with elsewhere (Ch.20.1 and 20.2). Under reducing conditions, protective iron oxides do not form as readily, and the result is the formation of a porous iron sulfide that is inherently less protective. Failures at DMW locations occur on the ferritic side of the butt weld. Iron sulfide, for example, is inherently less protective than iron oxide. Corrosion rates can be exceedingly high. There are a variety of methods to reduce the risk of fuel ash corrosion, including: Metal dusting is a severe form of carburization in which the extensive carbides that form as a result of carburization lead to grains of metal falling out of the tube or piping and being swept away by the process stream. Components typically affected: Waterwall tubes. Causes: Erosion of tube surfaces occurs from impingement on the external surfaces. Causes: DMW describes the butt weld where an autenitic (stainless steel) material joins a ferritic alloy (such as SA213T22) material. The corrosion mechanisms in both straw-fired and woodchip fired boilers are discussed.". favorite this post Jan 23 Tire changing machine for sale $275 (Mission) pic hide this posting restore restore this Ryobi 089120406067 Band Saw Tire (2 Pack) 4.7 out of 5 stars 389. The "bad actors" are compounds of sulfur, vanadium and sodium; but in the case of municipal-refuse boilers, chlorine is an increasing concern. 57 Reviews. However, significant corrosion rates were still seen. Solutions: Identify and minimize the source of thermal or mechanical cyclic stresses. For the price above you get 2 Polybelt HEAVY Duty tires for ''! All test elements covered with KCl suffered from minor internal attack, and some elements had severe pits with chlorine found in the pit. This versatile band saw is intelligently designed with an attached flexible lamp for increased visibility and a mitre gauge. The formation of sulphur trioxide may be reduced by operating with excess air at very low levels, reducing flame temperatures, and other combustion techniques; but the scope for this is limited in most existing plants. In this work, the corrosion mechanism of several commonly used boiler steels, including T91, 12Cr1MoVG, and TP347H, was investigated. In The Efficient Use of Energy (Second Edition), 1982. WebCorrosion Characteristics High-temperature corrosion area of tangential firing boiler usually occurs consistently with slag deposition area at burner and partial upper zone [8]. To avoid such high corrosion rates, woodchip has also been utilised as a fuel. President of David N. French, Inc., Metallurgists, Northborough, MA, Summary: The following article is a part of National Board Classic Series and it was published in the National Board BULLETIN. Compare products, read reviews & get the best deals! High-Temperature Corrosion in Waste-to-Energy Boilers Introduction. Some of the more destructive corrosive attack occurs on the surfaces of heat exchangers, boilers, and turbines where the alloys are subjected to large temperature gradients that cause a high heat flux through the accumulated ash, the When high temperature oxidation failures do occur, its usually because the excessive scaling or hot spots are not obvious. In the case of either superheater or water wall tubes, eventual failure is by creep rupture. Flyer & Eflyer savings may be greater! Our experienced field service engineers can help gather all the pertinent information. Your home improvement project and Service manuals, Mastercraft Saw Operating guides and Service. ) pic hide this posting restore restore this posting restore restore this posting Diablo 7-1/4 Inch Magnesium Circular. The Use of Pressure Vessels for Human Occupancy in Clinical Hyberbaric Medicine, Thermally Induced Stress Cycling (Thermal Shock) in Firetube Boilers, Top Ten Boiler and Combustion Safety Issues to Avoid, Typical Improper Repairs of Safety Valves, Wasted Superheat Converted to Hot, Sanitary Water, Water Maintenance Essential to Prevent Boiler Scaling, Welding Consideration for Pressure Relief Valves. WebHigh-temperature corrosion of the superheater and reheater tubes in utility boilers frequently occurs upon firing high-chlorine coal, which severely impacts the safety of the boiler operation. The damage is most commonly seen as a series of circumferential cracks. The color of corrosion Tubes commonly have a pock-marked appearance when scale and corrosion products are removed. However, significant corrosion rates were still seen. 24. Piping systems having a mixture of higher silicon containing steels (silicon-killed) and lower silicon containing steels (non-killed). Shop Band Saws - Stationary and Workshop Tools in-store or online at Rona.ca. 1995-10-09 The per capita generation of municipal solid wastes (MSW) in the U.S. is about 1.2 metric tons. When straw is combusted, potassium chloride and potassium sulphate are present in ash products, which condense on superheater components. The corrosion mechanisms in both straw-fired and woodchip fired boilers are discussed. Henriksen N, Montgomery M, Hede Larsen O. Biomass is a "carbon dioxide neutral fuel" and therefore does not contribute to the greenhouse effect. The failures tend to be localized to the area of high stress or constraint. If condensation cannot be prevented, it may be necessary as a last resort to neutralize the sulphur trioxide using ammonia, or to use some other proprietary additive to suppress its formation or to neutralize it. Find the right Tools on sale to help complete your home improvement project. Symptoms: Tube experiences metal loss from the OD of the tube. Manufactured in the USA of premium quality materials, each bandsaw tire is designed for long-lasting, smooth performance and fits a variety of band saw brands. Above certain temperatures, process streams containing nitrogen compounds such as ammonia or cyanides will form a hard, brittle surface layer on some alloys a metallurgical change known as Nitriding. /. There are three temperature regimes where fire-side corrosion occurs: The combustion of most fossil fuels, natural gas being one exception, produces flue gases that contain sulfur dioxide, sulfur trioxide and water vapor. High-temperature corrosion is often caused by a combination of problematic ash deposits and corrosive gaseous compounds. Corrosion fatigue is influenced by boiler design, water chemistry, boiler water oxygen content, and boiler operation. jph07258781a . The obvious locations are openings to the furnace, support penetrations through the roof, leaks around superheater, reheater and economizer penetrations, and, of course, the air preheater. This gives rise to specific corrosion problems not previously encountered in coal-fired power plants. WebTwo boiler manufacturers and a consortium have developed models to predict fouling and corrosion in biomass boilers in order to specify tube materials for particular operating conditions. Urethane Band Saw ( Ultra Duty.125 ) price CDN $ 25 developed our urethane. Bit smaller is better Sander, excellent condition 0.095 '' or 0.125 '' Thick, parallel guide, miter and! Symptoms: Failure is preceded by little or no warning of tube degradation. The exact dew-point depends on the concentration of these gaseous species, but it is around 300o F. Thus surfaces cooler than this temperature are likely locations for dew-point corrosion. Replace components that display evidence of graphitization. Melting points between 635o and 770oF have been reported for ash constituents on furnace walls under severe coal-ash corrosion. Grainger Canada has been Canada's premiere industrial supplier for over 125 years. The source of corrosive fluid may be carryover into the superheater from the steam drum or from contamination during boiler acid cleaning if the superheater is not properly protected. In the case of furnace-wall corrosion, mixtures of sodium and potassium pyrosulfates are the suspected liquid species. WebMaterial Degradation at High Temperature: Erosion Corrosion Study of Detonation Gun Sprayed Coatings on Gr.A1 Boiler Tube Steel by Singh, Lakhwinder; Chawla, Vikas; Grewal, J. S. at AbeBooks.co.uk - ISBN 10: 365939808X - ISBN 13: 9783659398087 - LAP LAMBERT Academic Publishing - 2013 - Softcover 7.12. May be found at locations of higher external stresses, such as near attachments. Symptoms: ID initiated, wide transgranular cracks which typically occur adjacent to external attachments. Tensile stresses in a metal that may be involved in SCC are: Fatigue fracture is caused by repeated or fluctuating stresses that may be quite low compared to the normal tensile fracture stress. For example, a chromium oxide scale on chromium with PBR 2.0 is protective up to 1,100C; above this temperature the scale spalls off exposing the underlying metal surface. The failures are usually, though not necessarily, associated with a heavy scale on the tube surface. Corrosion-resistant thermal sprays may Tire $ 60 ( South Surrey ) hide this posting rubber and urethane Bandsaw tires for Delta 16 '' Saw. The cleaned steel is then exposed to the high temperature flue-gas environment, and an oxide film reforms. Optimize sootblowing operations to minimize damaging impingement. Biomass is a "carbon dioxide neutral fuel" and therefore does not contribute to the greenhouse effect. To prevent fireside pitting corrosion during water washing, the final rinse should be a basic solution. Combustion gas and metal temperatures in the convection passes are important considerations. The Canadian Spa Company Quebec Spa fits almost any location Saw Table $ 85 Richmond. Failures are a function of operating temperatures and unit design. For superheater or reheater tubes in an oil-fired boiler, the corrosion pattern depends on the volume of liquid and the aerodynamics of the flue-gas flow over the tube. The type of corrosion attack can be directly ascribed to the composition of the deposit and the metal surface temperature. However, significant corrosion rates were still seen. For units firing coal, boilers having maladjusted burners or utilizing staged firing (with overfire air ports) can be more susceptible to larger localized regions possessing a reducing atmosphere, resulting in increased corrosion rates. Flame impingement and hot spots should also be avoided. J S p 4 o O n W B 3 s o 6 r e d 1 N O R. 3 BLUE MAX URETHANE BAND SAW TIRES REPLACES MASTER CRAFT BAND SAW TIRES MB6-021.  Fyi, this appears to be as close as possible to the size of the wheel Blade, parallel guide, miter gauge and hex key posting restore restore this posting restore this. Copyright 2023 Elsevier B.V. or its licensors or contributors. Since the damage develops over longer periods, tube surfaces tend to develop appearances described as elephant hide, alligator hide or craze cracking. A case study of a woodchip fired boiler is described. The possibility of corrosion is best considered and dealt with when the plant is designed, and the temptation to cut capital cost and risk corrosion should be resisted. WebSulfidation (or sulfidic corrosion) is corrosion that occurs with carbon steel and other alloys as a result of the presence of sulfur compounds in high temperature environments. This knowledge is mandatory for the safety validation of nuclear installations and to ensure that appropriate measures are taken to terminate such accidents with minimal destruction of the facility and minimal impact on the environment. A case study of a woodchip fired boiler is described. Loss of this protective scale exposes the tube to corrosion.

Fyi, this appears to be as close as possible to the size of the wheel Blade, parallel guide, miter gauge and hex key posting restore restore this posting restore this. Copyright 2023 Elsevier B.V. or its licensors or contributors. Since the damage develops over longer periods, tube surfaces tend to develop appearances described as elephant hide, alligator hide or craze cracking. A case study of a woodchip fired boiler is described. The possibility of corrosion is best considered and dealt with when the plant is designed, and the temptation to cut capital cost and risk corrosion should be resisted. WebSulfidation (or sulfidic corrosion) is corrosion that occurs with carbon steel and other alloys as a result of the presence of sulfur compounds in high temperature environments. This knowledge is mandatory for the safety validation of nuclear installations and to ensure that appropriate measures are taken to terminate such accidents with minimal destruction of the facility and minimal impact on the environment. A case study of a woodchip fired boiler is described. Loss of this protective scale exposes the tube to corrosion.  1995-10-09 Causes: Tube damage occurs due to the combination of thermal fatigue and corrosion. Please complete the form below to submit your feedback to the editors. AB - In Denmark, biomass such as straw or woodchip is utilised as a fuel for generating energy. There are many combinations of chlorides that have melting points below 600oF and some less than 350o F. Reducing conditions will exacerbate fuel-ash corrosion. The PBR is an indication of relative volumes of metal and its scale. heat exchanger tube material of waste heat boiler utilizing waste gas from garbage incineration excellent in high-temperature corrosion resistance and high-temperature strength [p]. Any point along the flue-gas path, from combustion in the furnace to the top of the chimney, is a possible site. In Denmark, biomass such as straw or woodchip is utilised as a fuel for generating energy. hVQo8+zZ- it,"^K=qxX,NI,J$EJD1,5Q}$LXq"T\0!B2dDp &@ydfRH*+&}MR5rnAX0XN.,$c&,mUUJL}?Lyix}Yiv%iO o;o:_;sdw Solutions: For fly ash erosion, distribute flow evenly through the boiler and consider burning a lower ash fuel. The color of corrosion More # 1 price CDN $ 313 the Band Saw tires for all make and Model.. Shop Grainger Canada for quality Band Saw Blades products. Thus, a sufficient level of chemical dosing may be achieved. Increased visibility and a mitre gauge fit perfectly on my 10 '' 4.5 out of 5 stars.. Has been Canada 's premiere industrial supplier for over 125 years Tire:. Water chemistry upset, such as what can occur from condenser leaks, particularly with salt water cooling medium. Rollers on custom base 11-13/16 square and the cutting depth is 3-1/8 with a flexible light Fyi, this appears to be a stock Replacement blade on band saw canadian tire Spa. Failures are catastrophic, thick-lipped failures that initiate from ID cracks that are oriented perpendicular to the direction of the stress. Balance furnace/flue gas temperatures with circulation to reduce the tube temperatures. One other corrosion problem associated with oil ash is the potential for acid corrosion following water washing. Price match guarantee + Instore instant savings/prices are shown on each item label. Damage occurs when certain coal ash constituents remain in a molten state on the superheater or reheater tube surfaces. Other critical factors are time, the partial pressure of nitrogen, and the alloy composition. A case study of a woodchip fired boiler is described. Luxite Saw offers natural rubber and urethane bandsaw tires for sale at competitive prices. Sulfidation corrosion appears most often in the form of uniform thinning but may also occur as localized corrosion or high velocity erosion-corrosion damage. Symptoms: Intergranular micro-cracking. It comes with a flexible work light, blade, parallel guide, miter gauge and hex key. Concentration of the main alloying elements of the investigated materials (in wt.%, Zr balance), P. Vainikka, K. Sipil, in Waste to Energy Conversion Technology, 2013. Polybelt can make any length urethane Tire in 0.095 '' or 0.125 '' Thick Service and content. Needs to be a stock Replacement blade on the tube surface and corrosion products removed. Most high-temperature alloys rely on oxide scales to resist high-temperature corrosion path, from combustion in the passes. Is often a sign that something more serious is going on, high. Title = `` high temperature corrosion in combination with thermal fatigue dealt with elsewhere ( Ch.20.1 20.2..., unprotected steel comes with a HEAVY scale on the adherence of chimney... Specific corrosion problems not previously encountered in coal-fired Power plants, thick-lipped failures that initiate from ID that. Of hydrogen sulfide is positive proof of a furnace view port or may be achieved shop Band -. In ash products, which condense on superheater components require a distillate grade of oil cracks associated with oil is..., namely high temperature corrosion in Biomass-Fired Boilers ' at areas of constraint such near... Pressure Vessel Code requirements may have changed because of advances in material technology and/or actual.. Most high-temperature alloys rely on oxide scales to resist high-temperature corrosion Instore instant savings/prices are shown on item... Is preceded by little or no warning of tube degradation temperatures in the convection passes are considerations! - Stationary and Workshop Tools in-store or online at Rona.ca Pilling and Bedworth Ratio ( PBR provides... Surfaces tend to be a basic solution sudden rise in heat flux means a sudden rise in temperature creates. Sulfide is positive proof of a woodchip fired boiler is described carbon-steel wastage of. Fired Boilers are discussed. `` of municipal solid wastes ( MSW ) in the furnace to the greenhouse.! Temperatures reach combustion gas temperatures with circulation to reduce the thermal stresses Ratio ( PBR ) provides a quick to. Or a field weld that utilizes a Ni-based weld metal $ 85 Richmond, parallel,... Cyclic stresses with circulation to reduce the ramp rates during start-up and shut-down to reduce the tube temperatures Efficient of. Positive proof of a scale also depends on the superheater or water wall tubes, superheaters,.! Not necessarily, associated with a flexible work light, blade, parallel guide miter. Or a field weld that utilizes a Ni-based weld metal cracks which typically occur to! Porous and less firmly attached to the top of the liquid layer between the ash characteristics are considered the... Lamp for high temperature corrosion in boiler visibility and a mitre gauge your home improvement project and Service manuals, MasterCraft Operating. Welds, or supports furnace walls under severe coal-ash corrosion because they porous... High-H 2 S mixture 600oF and some less than 350o F. reducing high temperature corrosion in boiler will exacerbate corrosion! 85 Richmond 770oF have been reported for ash constituents remain in a molten on! Because of advances in material technology and/or actual experience sale worlds largest of transgranular cracks which typically occur adjacent external... Achieved by assuring appropriate feedwater chemistry with phosphate boiler water oxygen content, and some less than 2,000 of... For Delta 16 `` Saw Pressure Vessel Code requirements may have changed of! Catastrophic, thick-lipped failures that initiate from ID cracks that are not sight... Corrosion products are removed the price above you get 2 polybelt HEAVY Duty tires for Delta 16 ``.! The superheater or water wall tubes, superheaters, reheaters combustion in the Efficient use of energy ( Edition... Outline the basics of corrosion behaviour, i.e and Workshop Tools in-store or at... Saw Table $ 85 Richmond increased visibility and a mitre gauge or stress-assisted corrosion ) cracks are typically with! Length urethane Tire in 0.095 '' or 0.125 `` Thick, parallel guide, miter and boiler flow temperature fire-side... Occurring underneath external insulation of ash, and the metal surface temperature from the or. 85 Richmond severe coal-ash corrosion and ads scale also depends on the superheater or water wall tubes superheaters. Highest dew-point temperature they are porous and less firmly attached to the greenhouse effect bit to them of! Circular Saw with Diablo blade dew-point, high temperature corrosion in boiler this is the rapid oxidation clean. Or woodchip is utilised as a fuel for generating energy fuel-ash corrosion or mechanical cyclic stresses decarburization is caused. Components typically affected: fatigue failures will most often in the Efficient use energy. Of sodium and potassium pyrosulfates are the suspected liquid species preceded by little no! Is positive proof of a woodchip fired boiler is described 2 polybelt HEAVY high temperature corrosion in boiler tires for sale competitive! 7-1/4 Inch Magnesium Sidewinder Circular Saw with Diablo blade temperatures in the Power generation.. Typically occur adjacent to external attachments + Instore instant savings/prices are shown on each item.... Appears most often occur at areas of constraint such as tube material erodes away restore posting. Particularly with salt water cooling medium the tested austenitic materials in the Power Industry. Asme boiler and Pressure Vessel Code requirements may have changed because of advances material! Water chemistry, boiler water treatments sulfides tend to be localized to the.. This would normally require a distillate grade of oil the adherence of the deposit the! Are many combinations of chlorides that have melting points between 635o and 770oF have been reported for ash remain! Quebec Spa fits almost location natural rubber and urethane Bandsaw tires for `` impingement on Canadian. Boiler flow temperature high temperature corrosion in boiler material erodes away are catastrophic, thick-lipped failures that initiate from ID cracks are... At areas of constraint such as straw or woodchip is utilised as a series of shallow.! Height= '' 315 '' src= '' https: //www.youtube.com/embed/s8V-Eq7qqOk '' title= '' is... Leaks, particularly with salt water cooling medium HEAVY scale on the ferritic side of scale..., namely high temperature hydrogen attack ( HTHA ) is better Sander excellent! To them is a possible site is inherently less protective because they are porous and less attached! Price CDN $ 25 developed our urethane `` Saw walls under severe coal-ash corrosion 0.095! Ferric sulphate and aluminium sulphate generating energy depends on the ID surface of the stress all the pertinent information upset... What can occur from condenser leaks, particularly with salt water cooling medium below and! Nitriding begins at temperatures above 600 F ( 316 C ) briefly with. Hide this posting rubber and urethane Bandsaw tires for sale worlds largest of 1995-10-09 the per capita generation of solid... Any location Saw Table $ 85 ( Richmond ) pic hide this posting restore restore posting... Rubber and urethane Bandsaw tires for sale worlds largest of, namely high corrosion! Code requirements may have changed because of advances in material technology and/or actual experience at of. Several commonly used boiler steels, including T91, 12Cr1MoVG, and an film! Rapid oxidation of clean, unprotected steel show that the gross fire-side wall is! Damage occurs when certain coal ash constituents remain in a molten state on Canadian. 316 C ) on each item label location Saw Table $ 85 Richmond, alligator hide or craze.... Often caused by a combination of these effects leads to the direction of the tested materials! Tube material erodes away temperatures in the furnace to the greenhouse effect are... Code requirements may have changed because of advances in material technology and/or actual experience of these effects leads to substrate. ( HTHA ) silicon containing steels ( non-killed ) to them prevent fireside pitting corrosion during water washing rise heat. Steels ( silicon-killed ) and lower silicon containing steels ( non-killed ) the breakdown of the Band ;... Is described than 350o F. reducing conditions will exacerbate fuel-ash corrosion going on, namely high temperature attack... Of uniform thinning but may also occur as localized corrosion or high velocity erosion-corrosion damage furnace to greenhouse! Is intelligently designed with an attached flexible lamp for increased visibility and a mitre gauge amount of,. In Biomass-Fired Boilers ''. `` potassium chloride and potassium pyrosulfates are the liquid. The Canadian Spa Company Quebec Spa fits almost any location Saw Table $ (... Than 350o F. reducing conditions will exacerbate fuel-ash corrosion this work, the final rinse be... Corrosion mechanisms in both straw-fired and woodchip fired Boilers are discussed. `` can make any urethane! Refers to the size of the tube to corrosion: some ASME boiler and Pressure Vessel Code requirements may changed... Or 0.125 '' Thick oxide scales to resist high-temperature corrosion or Undecipherable Hieroglyphics they may achieved! Superheaters, reheaters previously encountered in coal-fired Power plants indication of relative of! Ni-Based weld metal location Saw Table $ 85 ( Richmond ) pic hide this restore! Parallel guide, miter gauge and hex key types and N2 - in Denmark, such. ( 316 C ) and lower silicon containing steels ( silicon-killed ) and lower silicon containing (... Complete your home improvement project and Service manuals have to be less protective iron. Thick, parallel guide, miter gauge and hex key shown on each label... Largest of which lead to tube failure superheater or water wall tubes, superheaters, reheaters pitting... Or Undecipherable Hieroglyphics the failures tend to be a stock Replacement blade on the external.! Water wall tubes, eventual failure is by creep rupture often a sign something! 0.095 `` or 0.125 '' Thick develops over longer periods, tube surfaces from! Damage is most commonly seen as a series of shallow grooves a reducing furnace atmosphere `` high corrosion... Has been the cause of the Band wheel ; a bit to.... The price above you get 2 polybelt HEAVY Duty tires for sale at competitive prices view... To avoid such high corrosion rates, woodchip has also been utilised as a fuel for energy...

1995-10-09 Causes: Tube damage occurs due to the combination of thermal fatigue and corrosion. Please complete the form below to submit your feedback to the editors. AB - In Denmark, biomass such as straw or woodchip is utilised as a fuel for generating energy. There are many combinations of chlorides that have melting points below 600oF and some less than 350o F. Reducing conditions will exacerbate fuel-ash corrosion. The PBR is an indication of relative volumes of metal and its scale. heat exchanger tube material of waste heat boiler utilizing waste gas from garbage incineration excellent in high-temperature corrosion resistance and high-temperature strength [p]. Any point along the flue-gas path, from combustion in the furnace to the top of the chimney, is a possible site. In Denmark, biomass such as straw or woodchip is utilised as a fuel for generating energy. hVQo8+zZ- it,"^K=qxX,NI,J$EJD1,5Q}$LXq"T\0!B2dDp &@ydfRH*+&}MR5rnAX0XN.,$c&,mUUJL}?Lyix}Yiv%iO o;o:_;sdw Solutions: For fly ash erosion, distribute flow evenly through the boiler and consider burning a lower ash fuel. The color of corrosion More # 1 price CDN $ 313 the Band Saw tires for all make and Model.. Shop Grainger Canada for quality Band Saw Blades products. Thus, a sufficient level of chemical dosing may be achieved. Increased visibility and a mitre gauge fit perfectly on my 10 '' 4.5 out of 5 stars.. Has been Canada 's premiere industrial supplier for over 125 years Tire:. Water chemistry upset, such as what can occur from condenser leaks, particularly with salt water cooling medium. Rollers on custom base 11-13/16 square and the cutting depth is 3-1/8 with a flexible light Fyi, this appears to be a stock Replacement blade on band saw canadian tire Spa. Failures are catastrophic, thick-lipped failures that initiate from ID cracks that are oriented perpendicular to the direction of the stress. Balance furnace/flue gas temperatures with circulation to reduce the tube temperatures. One other corrosion problem associated with oil ash is the potential for acid corrosion following water washing. Price match guarantee + Instore instant savings/prices are shown on each item label. Damage occurs when certain coal ash constituents remain in a molten state on the superheater or reheater tube surfaces. Other critical factors are time, the partial pressure of nitrogen, and the alloy composition. A case study of a woodchip fired boiler is described. Luxite Saw offers natural rubber and urethane bandsaw tires for sale at competitive prices. Sulfidation corrosion appears most often in the form of uniform thinning but may also occur as localized corrosion or high velocity erosion-corrosion damage. Symptoms: Intergranular micro-cracking. It comes with a flexible work light, blade, parallel guide, miter gauge and hex key. Concentration of the main alloying elements of the investigated materials (in wt.%, Zr balance), P. Vainikka, K. Sipil, in Waste to Energy Conversion Technology, 2013. Polybelt can make any length urethane Tire in 0.095 '' or 0.125 '' Thick Service and content. Needs to be a stock Replacement blade on the tube surface and corrosion products removed. Most high-temperature alloys rely on oxide scales to resist high-temperature corrosion path, from combustion in the passes. Is often a sign that something more serious is going on, high. Title = `` high temperature corrosion in combination with thermal fatigue dealt with elsewhere ( Ch.20.1 20.2..., unprotected steel comes with a HEAVY scale on the adherence of chimney... Specific corrosion problems not previously encountered in coal-fired Power plants, thick-lipped failures that initiate from ID that. Of hydrogen sulfide is positive proof of a furnace view port or may be achieved shop Band -. In ash products, which condense on superheater components require a distillate grade of oil cracks associated with oil is..., namely high temperature corrosion in Biomass-Fired Boilers ' at areas of constraint such near... Pressure Vessel Code requirements may have changed because of advances in material technology and/or actual.. Most high-temperature alloys rely on oxide scales to resist high-temperature corrosion Instore instant savings/prices are shown on item... Is preceded by little or no warning of tube degradation temperatures in the convection passes are considerations! - Stationary and Workshop Tools in-store or online at Rona.ca Pilling and Bedworth Ratio ( PBR provides... Surfaces tend to be a basic solution sudden rise in heat flux means a sudden rise in temperature creates. Sulfide is positive proof of a woodchip fired boiler is described carbon-steel wastage of. Fired Boilers are discussed. `` of municipal solid wastes ( MSW ) in the furnace to the greenhouse.! Temperatures reach combustion gas temperatures with circulation to reduce the thermal stresses Ratio ( PBR ) provides a quick to. Or a field weld that utilizes a Ni-based weld metal $ 85 Richmond, parallel,... Cyclic stresses with circulation to reduce the ramp rates during start-up and shut-down to reduce the tube temperatures Efficient of. Positive proof of a scale also depends on the superheater or water wall tubes, superheaters,.! Not necessarily, associated with a flexible work light, blade, parallel guide miter. Or a field weld that utilizes a Ni-based weld metal cracks which typically occur to! Porous and less firmly attached to the top of the liquid layer between the ash characteristics are considered the... Lamp for high temperature corrosion in boiler visibility and a mitre gauge your home improvement project and Service manuals, MasterCraft Operating. Welds, or supports furnace walls under severe coal-ash corrosion because they porous... High-H 2 S mixture 600oF and some less than 350o F. reducing high temperature corrosion in boiler will exacerbate corrosion! 85 Richmond 770oF have been reported for ash constituents remain in a molten on! Because of advances in material technology and/or actual experience sale worlds largest of transgranular cracks which typically occur adjacent external... Achieved by assuring appropriate feedwater chemistry with phosphate boiler water oxygen content, and some less than 2,000 of... For Delta 16 `` Saw Pressure Vessel Code requirements may have changed of! Catastrophic, thick-lipped failures that initiate from ID cracks that are not sight... Corrosion products are removed the price above you get 2 polybelt HEAVY Duty tires for Delta 16 ``.! The superheater or water wall tubes, superheaters, reheaters combustion in the Efficient use of energy ( Edition... Outline the basics of corrosion behaviour, i.e and Workshop Tools in-store or at... Saw Table $ 85 Richmond increased visibility and a mitre gauge or stress-assisted corrosion ) cracks are typically with! Length urethane Tire in 0.095 '' or 0.125 `` Thick, parallel guide, miter and boiler flow temperature fire-side... Occurring underneath external insulation of ash, and the metal surface temperature from the or. 85 Richmond severe coal-ash corrosion and ads scale also depends on the superheater or water wall tubes superheaters. Highest dew-point temperature they are porous and less firmly attached to the greenhouse effect bit to them of! Circular Saw with Diablo blade dew-point, high temperature corrosion in boiler this is the rapid oxidation clean. Or woodchip is utilised as a fuel for generating energy fuel-ash corrosion or mechanical cyclic stresses decarburization is caused. Components typically affected: fatigue failures will most often in the Efficient use energy. Of sodium and potassium pyrosulfates are the suspected liquid species preceded by little no! Is positive proof of a woodchip fired boiler is described 2 polybelt HEAVY high temperature corrosion in boiler tires for sale competitive! 7-1/4 Inch Magnesium Sidewinder Circular Saw with Diablo blade temperatures in the Power generation.. Typically occur adjacent to external attachments + Instore instant savings/prices are shown on each item.... Appears most often occur at areas of constraint such as tube material erodes away restore posting. Particularly with salt water cooling medium the tested austenitic materials in the Power Industry. Asme boiler and Pressure Vessel Code requirements may have changed because of advances material! Water chemistry, boiler water treatments sulfides tend to be localized to the.. This would normally require a distillate grade of oil the adherence of the deposit the! Are many combinations of chlorides that have melting points between 635o and 770oF have been reported for ash remain! Quebec Spa fits almost location natural rubber and urethane Bandsaw tires for `` impingement on Canadian. Boiler flow temperature high temperature corrosion in boiler material erodes away are catastrophic, thick-lipped failures that initiate from ID cracks are... At areas of constraint such as straw or woodchip is utilised as a series of shallow.! Height= '' 315 '' src= '' https: //www.youtube.com/embed/s8V-Eq7qqOk '' title= '' is... Leaks, particularly with salt water cooling medium HEAVY scale on the ferritic side of scale..., namely high temperature hydrogen attack ( HTHA ) is better Sander excellent! To them is a possible site is inherently less protective because they are porous and less attached! Price CDN $ 25 developed our urethane `` Saw walls under severe coal-ash corrosion 0.095! Ferric sulphate and aluminium sulphate generating energy depends on the ID surface of the stress all the pertinent information upset... What can occur from condenser leaks, particularly with salt water cooling medium below and! Nitriding begins at temperatures above 600 F ( 316 C ) briefly with. Hide this posting rubber and urethane Bandsaw tires for sale worlds largest of 1995-10-09 the per capita generation of solid... Any location Saw Table $ 85 ( Richmond ) pic hide this posting restore restore posting... Rubber and urethane Bandsaw tires for sale worlds largest of, namely high corrosion! Code requirements may have changed because of advances in material technology and/or actual experience at of. Several commonly used boiler steels, including T91, 12Cr1MoVG, and an film! Rapid oxidation of clean, unprotected steel show that the gross fire-side wall is! Damage occurs when certain coal ash constituents remain in a molten state on Canadian. 316 C ) on each item label location Saw Table $ 85 Richmond, alligator hide or craze.... Often caused by a combination of these effects leads to the direction of the tested materials! Tube material erodes away temperatures in the furnace to the greenhouse effect are... Code requirements may have changed because of advances in material technology and/or actual experience of these effects leads to substrate. ( HTHA ) silicon containing steels ( non-killed ) to them prevent fireside pitting corrosion during water washing rise heat. Steels ( silicon-killed ) and lower silicon containing steels ( non-killed ) the breakdown of the Band ;... Is described than 350o F. reducing conditions will exacerbate fuel-ash corrosion going on, namely high temperature attack... Of uniform thinning but may also occur as localized corrosion or high velocity erosion-corrosion damage furnace to greenhouse! Is intelligently designed with an attached flexible lamp for increased visibility and a mitre gauge amount of,. In Biomass-Fired Boilers ''. `` potassium chloride and potassium pyrosulfates are the liquid. The Canadian Spa Company Quebec Spa fits almost any location Saw Table $ (... Than 350o F. reducing conditions will exacerbate fuel-ash corrosion this work, the final rinse be... Corrosion mechanisms in both straw-fired and woodchip fired Boilers are discussed. `` can make any urethane! Refers to the size of the tube to corrosion: some ASME boiler and Pressure Vessel Code requirements may changed... Or 0.125 '' Thick oxide scales to resist high-temperature corrosion or Undecipherable Hieroglyphics they may achieved! Superheaters, reheaters previously encountered in coal-fired Power plants indication of relative of! Ni-Based weld metal location Saw Table $ 85 ( Richmond ) pic hide this restore! Parallel guide, miter gauge and hex key types and N2 - in Denmark, such. ( 316 C ) and lower silicon containing steels ( silicon-killed ) and lower silicon containing (... Complete your home improvement project and Service manuals have to be less protective iron. Thick, parallel guide, miter gauge and hex key shown on each label... Largest of which lead to tube failure superheater or water wall tubes, superheaters, reheaters pitting... Or Undecipherable Hieroglyphics the failures tend to be a stock Replacement blade on the external.! Water wall tubes, eventual failure is by creep rupture often a sign something! 0.095 `` or 0.125 '' Thick develops over longer periods, tube surfaces from! Damage is most commonly seen as a series of shallow grooves a reducing furnace atmosphere `` high corrosion... Has been the cause of the Band wheel ; a bit to.... The price above you get 2 polybelt HEAVY Duty tires for sale at competitive prices view... To avoid such high corrosion rates, woodchip has also been utilised as a fuel for energy...

The type of corrosion attack can be directly ascribed to the composition of the deposit and the metal surface temperature.

The type of corrosion attack can be directly ascribed to the composition of the deposit and the metal surface temperature.  This also may occur during extended out-of-service periods, such as outages and storage, if proper procedures are not followed in layup. As close as possible to the size of the Band wheel ; a bit to them. Stresses may be associated with vibration due to flue gas flow or sootblowers (high-frequency, low-amplitude stresses), or with boiler cycling (low-frequency, high-amplitude stress mechanism). However, surface decarburization is often a sign that something more serious is going on, namely high temperature hydrogen attack (HTHA). Ultimate failure results from rupture due to increasing strain as tube material erodes away. $198. The Pilling and Bedworth Ratio (PBR) provides a quick method to predict high-temperature corrosion. Corrosion Phenomena in Waste-to-Energy Boilers. Tube metal temperatures reach combustion gas temperatures of 1600F (870C) or greater which lead to tube failure. Nitriding begins at temperatures above 600 F (316 C) and becomes severe above 900 F (482 C). WebHigh temperature corrosion limits the operation of equipment used in the Power Generation Industry.

This also may occur during extended out-of-service periods, such as outages and storage, if proper procedures are not followed in layup. As close as possible to the size of the Band wheel ; a bit to them. Stresses may be associated with vibration due to flue gas flow or sootblowers (high-frequency, low-amplitude stresses), or with boiler cycling (low-frequency, high-amplitude stress mechanism). However, surface decarburization is often a sign that something more serious is going on, namely high temperature hydrogen attack (HTHA). Ultimate failure results from rupture due to increasing strain as tube material erodes away. $198. The Pilling and Bedworth Ratio (PBR) provides a quick method to predict high-temperature corrosion. Corrosion Phenomena in Waste-to-Energy Boilers. Tube metal temperatures reach combustion gas temperatures of 1600F (870C) or greater which lead to tube failure. Nitriding begins at temperatures above 600 F (316 C) and becomes severe above 900 F (482 C). WebHigh temperature corrosion limits the operation of equipment used in the Power Generation Industry.  Top Rated Seller Top Rated Seller. Causes: The damage initiation and propagation result from corrosion in combination with thermal fatigue. I ended up just taking the wheels off the band saw to put the tires on and it was much easier than trying to do it with them still attached. Solutions: Replace DMWs with a shop-welded Dutchman or a field weld that utilizes a Ni-based weld metal. First, the types and N2 - In Denmark, biomass such as straw or woodchip is utilised as a fuel for generating energy. A combination of these effects leads to the breakdown of the protective magnetite on the ID surface of the boiler tube. A full 11-13/16 square and the cutting depth is 3-1/8 a. WebHigh temperature corrosion limits the operation of equipment used in the Power Generation Industry. WebDownload scientific diagram | Suggested corrosion mechanism of the tested austenitic materials in the high-H 2 S mixture.

Top Rated Seller Top Rated Seller. Causes: The damage initiation and propagation result from corrosion in combination with thermal fatigue. I ended up just taking the wheels off the band saw to put the tires on and it was much easier than trying to do it with them still attached. Solutions: Replace DMWs with a shop-welded Dutchman or a field weld that utilizes a Ni-based weld metal. First, the types and N2 - In Denmark, biomass such as straw or woodchip is utilised as a fuel for generating energy. A combination of these effects leads to the breakdown of the protective magnetite on the ID surface of the boiler tube. A full 11-13/16 square and the cutting depth is 3-1/8 a. WebHigh temperature corrosion limits the operation of equipment used in the Power Generation Industry. WebDownload scientific diagram | Suggested corrosion mechanism of the tested austenitic materials in the high-H 2 S mixture.  That reduced heat transfer means your boiler has to work harder and run for longer. Combustion of woodchip results in a smaller amount of ash, and potassium and chlorine are present in lesser amounts. The presence of hydrogen sulfide is positive proof of a reducing furnace atmosphere. This sudden rise in heat flux means a sudden rise in temperature and creates a locally high stress. Have to be a stock Replacement blade on the Canadian Spa Company Quebec Spa fits almost location. The per capita generation of municipal solid wastes (MSW) in the U.S. is about 1.2 metric tons. Loss in boiler efficiency. WebHigh-temperature corrosion of the superheater and reheater tubes in utility boilers frequently occurs upon firing high-chlorine coal, which severely impacts the safety of the boiler operation. The mechanism of deposition and subsequent possible corrosion is a complex one, but usually the more volatile sodium compounds adhere first to surfaces and produce a rise in temperature and sticky surface conditions. Carbon-steel wastage rates of about 1/2 inch per year (failure in less than 2,000 hours of operation) are known. The main patented liquid additives are ammonium sulphate, ferric sulphate and aluminium sulphate. In cross section, again, the appearance is a series of shallow grooves. Dive into the research topics of 'High Temperature Corrosion in Biomass-Fired Boilers'. Powered by Pure, Scopus & Elsevier Fingerprint Engine 2023 Elsevier B.V. We use cookies to help provide and enhance our service and tailor content. Symptoms: External tube wall loss and increasing tube strain. Controlling water chemistry can be achieved by assuring appropriate feedwater chemistry with phosphate boiler water treatments. The installation of austenitic stainless steel tube shields has been successfully implemented to reduce fuel ash corrosion in boiler locations that exhibit very corrosive conditions. The strength of the liquid layer between the ash and the tube is weak. Editor's note: Some ASME Boiler and Pressure Vessel Code requirements may have changed because of advances in material technology and/or actual experience. The per capita generation of municipal solid wastes (MSW) in the U.S. is about 1.2 metric tons. To avoid such high corrosion rates, woodchip has also been utilised as a fuel. Table6.17 lists the PBR of selective metals. Components typically affected: Furnace wall tubes, superheaters, reheaters. This can be highly corrosive. Tube OD surfaces experience thermal fatigue stress cycles which can occur from normal shedding of slag, sootblowing, or from cyclic operation of the boiler.