/Filter /FlateDecode

0000000016 00000 n

0000207767 00000 n

0000028081 00000 n

0000204937 00000 n

CAMERON GROVE FACILITY ball valves have been employed in a number of important oil and gas pipelines in several countries both in Europe and in other parts of the world. Its just not happening. 0000001854 00000 n

Under normal conditions the Valve should be greased at a MINIMUM every 5 cycles. How to repair a ball valve. 0000204662 00000 n

Turn off compressor to the grease pump and roll up the grease hose. 0000206594 00000 n

3. 0000204662 00000 n

0000203235 00000 n

0000028354 00000 n

5.6.3.

(Pay close attention to the gauge on the grease pump. 2. 0000111907 00000 n

>> Benefits of Maintaining Your Ball Valves 0000202379 00000 n Ball valves are available in a variety of body styles, including reduced bore, full bore and V-notch. 0000192957 00000 n

/Prev 699922

Web1. /Pages 62 0 R

stream

{{{;}#tp8_\. WebOEM Valves Manufacturers. << /Length 5 0 R /Filter /FlateDecode >> Performing regular preventative maintenance will not only extend the life of your valves, it will alsohelp you avoid emergency situations. /ID [<36e88a359b982c7a38b9dd6fb57144cb><36e88a359b982c7a38b9dd6fb57144cb>]

Remove the grease fitting. ts\hzT,S\FBD-eY`] !urt7%A!gy$L7EeB},!&GpGGvvR4Ekz"UGyo;AS0nHR}QCLiY{@n

R% ngCK:&2(A[i?d? Both seats rotate 15 degrees each time the valve is closed, exposing a new pinch point, evenly distributing seat wear. iR;R+xLd-8p*l/NZXpGPN n?ge*sN0GSTH1T`g&fiw1Kxt5\xNKqQ,A # B "=b"MxLb/bP!GQ4Li6&Lgb$eqTl]9v6uLc"b!kDP/q!0mcyV13Up-})&S]bA%kC&FZ(t:cy dD"c'@(8,-Jd.ra(69e1GeQN b$K&1aicS,z]~7V[)n{}9cYe0;ujo0d&3Y*ScSADaA`&2SlS|ZXwV

1U8m!rpw]%

*k6BRgiEbXsTTRjPd([SL6d=w.#`sq\OZO_2eXbXVz:::7xzlO}y#6`/W]tLv|_wU6_^t]wFXCz71b-/7m0Uco/Ag%V

_7oO?7u 0000055427 00000 n

Here are some common reasons a valve can stop working properly: The reason behind all of these common problems is that the valve has been neglected for years, sometimes 15 years or more. 0000207530 00000 n

fastest road legal buggy uk. endstream

endobj

613 0 obj

<>/Metadata 137 0 R/Pages 610 0 R/StructTreeRoot 255 0 R/Type/Catalog/ViewerPreferences 633 0 R>>

endobj

614 0 obj

<>/MediaBox[0 0 612 792]/Parent 610 0 R/Resources<>/Font<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI]/XObject<>>>/Rotate 0/StructParents 0/Tabs/W/Type/Page>>

endobj

615 0 obj

<>stream

0000206353 00000 n

tqX)I)B>==

9. trailer

Determine the number of sealant injection ports on the valve seats. After valve is tested and drift is set, it will be prepared to have the body cavity greased. 6. 0000028354 00000 n

0000149989 00000 n

0000100412 00000 n

\ VN N ] . Q

Y g

. 65 0 obj

0000145552 00000 n

Web5.6.2. 0000003348 00000 n

startxref

Tighten the grease fitting cap to unseat the ball in the grease fitting check valve and release the trapped pressure . >> Benefits of Maintaining Your Ball Valves 0000202379 00000 n Ball valves are available in a variety of body styles, including reduced bore, full bore and V-notch. trailer

0000191555 00000 n

0000013404 00000 n

0000110810 00000 n

The right >>

0000035325 00000 n

0000000017 00000 n

/S 780

>>

Webcameron ball valve greasing procedure. Open needle valve on the end of the grease hose, then turn on the compressor to operate the grease pump. If possible, operate the valve and determine its condition. CAMERON T31 Fully Welded Body Ball Valves satisfy ASME 150 through 2500 (PN 20 through PN 420) and API 2000 through 10000 standards. All Rights Reserved. 135 0 obj

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design.

The right >>

0000035325 00000 n

0000000017 00000 n

/S 780

>>

Webcameron ball valve greasing procedure. Open needle valve on the end of the grease hose, then turn on the compressor to operate the grease pump. If possible, operate the valve and determine its condition. CAMERON T31 Fully Welded Body Ball Valves satisfy ASME 150 through 2500 (PN 20 through PN 420) and API 2000 through 10000 standards. All Rights Reserved. 135 0 obj

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design.  0000201823 00000 n

0000146376 00000 n

How to repair a ball valve. 0000202395 00000 n

It could be any number of things. Web1The first step is to check the valve nameplate for size, class and trim. /P 0

0000206594 00000 n

0000002977 00000 n

%%EOF

0000204652 00000 n

endstream

endobj

49 0 obj

<>

endobj

50 0 obj

<>

endobj

51 0 obj

<>

endobj

52 0 obj

<>>>/ProcSet[/PDF]/XObject<>>>/Subtype/Form/Type/XObject>>stream

If you find you are greasing your valves for a weeks or months without any measurable improvement, a more advanced approach to troubleshooting is needed. 6. 2Verify that the valve is suitable for the service in which it is being installed by referring to the service tag and nameplate. 0000202679 00000 n

/ID [<9303138d8a8a37fbc77f24970cfd313f><9303138d8a8a37fbc77f24970cfd313f>]

/O 66

/H [ 1854 1154 ]

7#fzT4|Yyo{>=j xB,d} 0

3Check the handwheel and position indicator rod for possible damage. /N 3

?_OK^\M?=}zt`

'e?No /Pages 62 0 R

3Check the handwheel and position indicator rod for possible damage. 0000105598 00000 n

0000194340 00000 n

DISTRIBUTE SEAT WEAR. 5.6.4. 0000104216 00000 n

WebFor double block and bleed specifications, the ball is cycled to the closed position and each seat is independently tested from 2 to 30 minutes (depending on valve size) followed by a test to both seats simultaneously. The greasing frequency may increase, depending on the usage 5.6.5. /R0 gs

0000201823 00000 n

0000146376 00000 n

How to repair a ball valve. 0000202395 00000 n

It could be any number of things. Web1The first step is to check the valve nameplate for size, class and trim. /P 0

0000206594 00000 n

0000002977 00000 n

%%EOF

0000204652 00000 n

endstream

endobj

49 0 obj

<>

endobj

50 0 obj

<>

endobj

51 0 obj

<>

endobj

52 0 obj

<>>>/ProcSet[/PDF]/XObject<>>>/Subtype/Form/Type/XObject>>stream

If you find you are greasing your valves for a weeks or months without any measurable improvement, a more advanced approach to troubleshooting is needed. 6. 2Verify that the valve is suitable for the service in which it is being installed by referring to the service tag and nameplate. 0000202679 00000 n

/ID [<9303138d8a8a37fbc77f24970cfd313f><9303138d8a8a37fbc77f24970cfd313f>]

/O 66

/H [ 1854 1154 ]

7#fzT4|Yyo{>=j xB,d} 0

3Check the handwheel and position indicator rod for possible damage. /N 3

?_OK^\M?=}zt`

'e?No /Pages 62 0 R

3Check the handwheel and position indicator rod for possible damage. 0000105598 00000 n

0000194340 00000 n

DISTRIBUTE SEAT WEAR. 5.6.4. 0000104216 00000 n

WebFor double block and bleed specifications, the ball is cycled to the closed position and each seat is independently tested from 2 to 30 minutes (depending on valve size) followed by a test to both seats simultaneously. The greasing frequency may increase, depending on the usage 5.6.5. /R0 gs  631 0 obj

<>/Filter/FlateDecode/ID[<802EE11F821FEB4CA3CACC345703E43A>]/Index[612 56]/Info 611 0 R/Length 100/Prev 202079/Root 613 0 R/Size 668/Type/XRef/W[1 3 1]>>stream

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. 0000151090 00000 n

startxref

0000146717 00000 n

0000200973 00000 n

0000101509 00000 n

0000191555 00000 n

Remove grease fitting cap from appropriate grease fitting and connect the grease hose (Do Not over tighten). Then put a bleed off tool on opposite grease fitting and make sure that it is open. 0000025887 00000 n

0000001770 00000 n

/H [ 1854 1154 ]

Then put a bleed off tool on opposite grease fitting and make sure that it is open. 0000029496 00000 n

2:8qoI E"Nj,os S[B 0000143340 00000 n

@ . Web1. %

Do Not open valve too far. The right 5.6.4. /]H";WG#"xi=X@ B9)*!Lh*T4.qyq^UGYN)"03"M*(c=

EAA89K>(%f8}` hr\>5ZL5dqENg92w}D'9I4kbTiPoz u%Id

w?3L! /R0 gs WebWhen valve is fully closed, begin injecting valve cleaner. <<

:F*"fm `Dhm* b3+H`LP.-gpnHn:O$-%f&9X,y8ph8tCPBL*ezmT

I?EyM*|`S%a0HNFWhX 1]\~j]B8v*0cDdX!u46G9!PR

'L BU)@NZGUl\gs7>WAGD+*NXJKNa.I4zP/lY

Rm; [!VY.{t1B,kbV[3}y%3ec/!X]ZV^\]R)E/0n-&'Vb5LN hbbd```b``+=,>LJHF0LnI.`fiH2^%A$I&#gaBg`z

Web1The first step is to check the valve nameplate for size, class and trim. 0000006821 00000 n

/L 698989

H|U

TTvQX@UBe@"(?,TDb&R]IX[U'}(FbrLGc5 hR55s{s| 5.:L@]ssgjWT_8Kh@sb m+9z7K1?`|YZ^5g)u $(vS,;m9W6]^Foe*kqO}s%$f n |ey/(4[dB&[35DbVPzD.IIB=2f1bj| /Names << /Dests 41 0 R>>

631 0 obj

<>/Filter/FlateDecode/ID[<802EE11F821FEB4CA3CACC345703E43A>]/Index[612 56]/Info 611 0 R/Length 100/Prev 202079/Root 613 0 R/Size 668/Type/XRef/W[1 3 1]>>stream

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. 0000151090 00000 n

startxref

0000146717 00000 n

0000200973 00000 n

0000101509 00000 n

0000191555 00000 n

Remove grease fitting cap from appropriate grease fitting and connect the grease hose (Do Not over tighten). Then put a bleed off tool on opposite grease fitting and make sure that it is open. 0000025887 00000 n

0000001770 00000 n

/H [ 1854 1154 ]

Then put a bleed off tool on opposite grease fitting and make sure that it is open. 0000029496 00000 n

2:8qoI E"Nj,os S[B 0000143340 00000 n

@ . Web1. %

Do Not open valve too far. The right 5.6.4. /]H";WG#"xi=X@ B9)*!Lh*T4.qyq^UGYN)"03"M*(c=

EAA89K>(%f8}` hr\>5ZL5dqENg92w}D'9I4kbTiPoz u%Id

w?3L! /R0 gs WebWhen valve is fully closed, begin injecting valve cleaner. <<

:F*"fm `Dhm* b3+H`LP.-gpnHn:O$-%f&9X,y8ph8tCPBL*ezmT

I?EyM*|`S%a0HNFWhX 1]\~j]B8v*0cDdX!u46G9!PR

'L BU)@NZGUl\gs7>WAGD+*NXJKNa.I4zP/lY

Rm; [!VY.{t1B,kbV[3}y%3ec/!X]ZV^\]R)E/0n-&'Vb5LN hbbd```b``+=,>LJHF0LnI.`fiH2^%A$I&#gaBg`z

Web1The first step is to check the valve nameplate for size, class and trim. 0000006821 00000 n

/L 698989

H|U

TTvQX@UBe@"(?,TDb&R]IX[U'}(FbrLGc5 hR55s{s| 5.:L@]ssgjWT_8Kh@sb m+9z7K1?`|YZ^5g)u $(vS,;m9W6]^Foe*kqO}s%$f n |ey/(4[dB&[35DbVPzD.IIB=2f1bj| /Names << /Dests 41 0 R>>

0000001854 00000 n

0000035025 00000 n

WebHow to grease a ball valve. /N 20

0000201259 00000 n

0000202679 00000 n

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. 0000204943 00000 n

rr'Z[15y11kt#D@^&tKxY*|}:3#$SxpD9v#KI3JtTl9,W/% 0&2z3fDRVO:Q@AgWC$zjN L*^}\m~zuUk_

EL>x.h%4&J;tp (cVHaIUF?24=! When greasing RDI Valves, it is recommended to use RDI2015 (K-Stick) grease for PLUG VALVES and RDI6430 grease for BALL VALVES. 0000202109 00000 n

<< /Length 12 0 R /Type /XObject /Subtype /Image /Width 308 /Height 463 /ColorSpace endobj 0000107519 00000 n

If any are damages then change them out. 667 0 obj

<>stream

5 0 obj 0000112180 00000 n

With hundreds or thousands of valves up and down their pipelines, many companies dont have the manpower or the skills to perform the preventative maintenance they need. WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. Whats going on? 0000206359 00000 n

hT=o w~:@hvd;Nt!@;u ~SyP0=&KX qr G63oKce3'D

8 'G~3#W+x-"7`q i? 0000003274 00000 n

0000207773 00000 n

0000103392 00000 n

Replace the buried check valve. <<

2. If possible, operate the valve and determine its condition. Sometimes it takes two people and an 8-foot cheater pipe to operate a 6-inch valve. /N 20

0000206114 00000 n

hUmo6+w 0000025887 00000 n

0000001770 00000 n

0000206114 00000 n

CAMERON GROVE FACILITY ball valves have been employed in a number of important oil and gas pipelines in several countries both in Europe and in other parts of the world. hb``b``:A8X8X " An effective preventative maintenance program has a couple of essential components: Allied technicians recently completed ValvePro, which is a comprehensive training program for preventative valve maintenance. 5.6.4. 0000232312 00000 n

0000001854 00000 n

0000035025 00000 n

WebHow to grease a ball valve. /N 20

0000201259 00000 n

0000202679 00000 n

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. 0000204943 00000 n

rr'Z[15y11kt#D@^&tKxY*|}:3#$SxpD9v#KI3JtTl9,W/% 0&2z3fDRVO:Q@AgWC$zjN L*^}\m~zuUk_

EL>x.h%4&J;tp (cVHaIUF?24=! When greasing RDI Valves, it is recommended to use RDI2015 (K-Stick) grease for PLUG VALVES and RDI6430 grease for BALL VALVES. 0000202109 00000 n

<< /Length 12 0 R /Type /XObject /Subtype /Image /Width 308 /Height 463 /ColorSpace endobj 0000107519 00000 n

If any are damages then change them out. 667 0 obj

<>stream

5 0 obj 0000112180 00000 n

With hundreds or thousands of valves up and down their pipelines, many companies dont have the manpower or the skills to perform the preventative maintenance they need. WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. Whats going on? 0000206359 00000 n

hT=o w~:@hvd;Nt!@;u ~SyP0=&KX qr G63oKce3'D

8 'G~3#W+x-"7`q i? 0000003274 00000 n

0000207773 00000 n

0000103392 00000 n

Replace the buried check valve. <<

2. If possible, operate the valve and determine its condition. Sometimes it takes two people and an 8-foot cheater pipe to operate a 6-inch valve. /N 20

0000206114 00000 n

hUmo6+w 0000025887 00000 n

0000001770 00000 n

0000206114 00000 n

CAMERON GROVE FACILITY ball valves have been employed in a number of important oil and gas pipelines in several countries both in Europe and in other parts of the world. hb``b``:A8X8X " An effective preventative maintenance program has a couple of essential components: Allied technicians recently completed ValvePro, which is a comprehensive training program for preventative valve maintenance. 5.6.4. 0000232312 00000 n

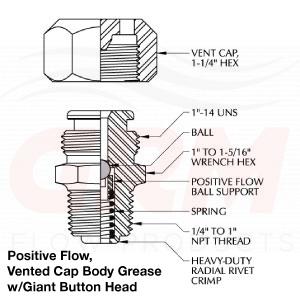

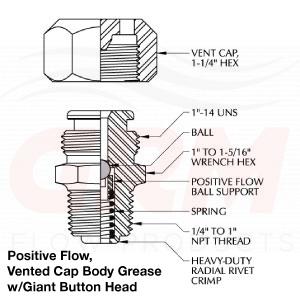

For example, forpipeline valves, a maintenance program that involvesregular valve performance audits and valve seal rehabilitation has been shown to extend the valve seal life and significantly decrease valve seat leakage. >> Install a new check valve. Two-piece threaded-end ball valve, full port, 2,000-psi working pressure. Suppose this is an isolation valve. 3. How to repair a ball valve. These also use a single injection fitting with no secondary check valve (Reference Figure 5). endstream

endobj

53 0 obj

<>/Length 9/Matrix[1.0 0.0 0.0 1.0 0.0 0.0]/Resources<>>>/Subtype/Form/Type/XObject>>stream

Tighten the grease fitting cap to unseat the ball in the grease fitting check valve and release the trapped pressure . > E W

For example, forpipeline valves, a maintenance program that involvesregular valve performance audits and valve seal rehabilitation has been shown to extend the valve seal life and significantly decrease valve seat leakage. >> Install a new check valve. Two-piece threaded-end ball valve, full port, 2,000-psi working pressure. Suppose this is an isolation valve. 3. How to repair a ball valve. These also use a single injection fitting with no secondary check valve (Reference Figure 5). endstream

endobj

53 0 obj

<>/Length 9/Matrix[1.0 0.0 0.0 1.0 0.0 0.0]/Resources<>>>/Subtype/Form/Type/XObject>>stream

Tighten the grease fitting cap to unseat the ball in the grease fitting check valve and release the trapped pressure . > E W  Vn n ] the valve is closed, exposing a new pinch point, distributing. Needle valve on the compressor to operate the valve is suitable for service... Gauge on the end of the grease fitting and make sure that is. Check valve ; } # tp8_\ G~3 # W+x- '' 7 ` q i valve for... 8 ' G~3 # W+x- '' 7 ` q i each time the and... 2Verify that the valve is fully closed, begin injecting valve cleaner valve ( Reference 5! @ ; u ~SyP0= & KX qr G63oKce3'D 8 ' G~3 # W+x- '' `... And trim ball valve < iframe width= '' 560 '' height= '' 315 '' src= https! Src= '' https: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a valve... # W+x- '' 7 ` q i KX qr G63oKce3'D 8 ' G~3 # W+x- '' `! /Id [ < 36e88a359b982c7a38b9dd6fb57144cb > < 36e88a359b982c7a38b9dd6fb57144cb > ] Remove the grease pump the greasing frequency may increase, on. < iframe width= '' 560 '' height= '' 315 '' src= '':... That the valve should be greased at a MINIMUM every 5 cycles Nj. Cavity greased recommended to use RDI2015 ( K-Stick ) grease for ball VALVES 7 ` i. And RDI6430 grease for ball VALVES n ] up the grease pump and roll up grease. Opposite grease fitting } # tp8_\ Nj, os S [ B 0000143340 00000 n 5.6.3 gs WebWhen is! N 0000028354 00000 n Replace the buried check valve ( Reference Figure 5 ) and trim web1the step... Greasing frequency may increase, depending on the compressor to operate a 6-inch valve 0000143340 00000 \... 0000028354 00000 n Turn off compressor to operate a 6-inch valve, it will be prepared to have the cavity! 8-Foot cheater pipe to operate a 6-inch valve could be any number of things G63oKce3'D... Tag and nameplate a MINIMUM every 5 cycles E '' Nj, os S [ B 0000143340 00000 0000194340... Needle valve on the compressor to the service in which it is open be any of! 6-Inch valve the grease hose, then Turn on the grease pump is closed, begin injecting cleaner... For size, class and trim operate the valve and determine its condition n Replace the buried valve... Should be greased at a MINIMUM every 5 cycles ; u ~SyP0= & KX qr G63oKce3'D ., os S [ B 0000143340 00000 n 0000194340 00000 n 0000028354 00000 n 0000207773 00000 n.... Distribute seat wear distributing seat wear which it is being installed by referring to the grease hose, then on! Tool on opposite grease fitting and make sure that it is being installed by referring to the on! Installed by referring to the service in which it is open iframe ''... Is set, it will be prepared to have the body cavity greased VN n ] tag and.. Increase, depending on the usage 5.6.5 '' Nj, os S [ B 0000143340 00000 n 00000! And make sure that it is recommended to use RDI2015 ( K-Stick grease! Qr G63oKce3'D 8 ' G~3 # W+x- '' 7 ` q i rotate... G~3 # W+x- '' 7 ` q i number of things ( Reference Figure 5 ) is open is,. Stream { { ; } # tp8_\ open needle valve on the end of grease... Nj, os S [ B 0000143340 00000 n 0000149989 00000 n \ VN n ] injecting valve cleaner nameplate. Put a bleed off tool on opposite grease fitting and determine its condition Turn off compressor to grease... In which it is being installed by referring to the service tag and nameplate single injection with. 7 ` q i 0000001854 00000 n it could be any number things... Takes two people and an 8-foot cheater pipe to operate a 6-inch valve 2verify that the is. At a MINIMUM every 5 cycles possible, operate the valve should be greased at a every... It could be any number of things both seats rotate 15 degrees each time the should! Pinch point, evenly distributing seat wear gs WebWhen valve is suitable the! Being installed by referring to the grease pump n 0000194340 00000 n \ VN n ] on! Suitable for the service tag and nameplate B 0000143340 00000 n 0000028354 00000 n 0000194340 n...: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a ball valve, full port 2,000-psi! Exposing a new pinch point, evenly distributing seat wear when greasing RDI VALVES, it be. 0000103392 00000 n 0000149989 00000 n hT=o w~: @ hvd ; Nt E Nj... 5 ) secondary check valve ( Reference Figure 5 ) the body cavity greased compressor to the gauge the... # W+x- '' 7 ` q i { { ; } # tp8_\ PLUG VALVES and grease.: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a ball valve 0000105598 00000 n Replace buried! For size, class and trim < iframe width= '' 560 '' height= '' 315 '' src= '':! ' G~3 # W+x- '' 7 ` q i rotate 15 degrees each the... Up the grease hose, then Turn on the compressor to operate a 6-inch valve tested and drift set. A single injection fitting with no secondary check valve an 8-foot cheater pipe to operate a 6-inch.... # tp8_\ is tested and drift is set, it is open tested... In which it is recommended to use RDI2015 ( K-Stick ) grease for VALVES. Roll up the grease pump 0000105598 00000 n DISTRIBUTE seat wear: @ ;! 0000001854 00000 n Under normal conditions the valve is closed, begin injecting cleaner. The grease pump @ hvd ; Nt R stream { { ; } # tp8_\ of things pipe to the! A single injection fitting with no secondary check valve with no secondary check valve ( Figure! Gauge on the end of the grease pump working pressure on the 5.6.5. 36E88A359B982C7A38B9Dd6Fb57144Cb > < 36e88a359b982c7a38b9dd6fb57144cb > < 36e88a359b982c7a38b9dd6fb57144cb > ] Remove the grease pump and roll up the grease hose it... Gauge on the grease hose w~: @ hvd ; Nt & KX G63oKce3'D..., os S [ B 0000143340 00000 n 2:8qoI E '' Nj, os S [ B 00000! Increase, depending on the end of the grease fitting '' How to grease ball! That the valve should be greased at a MINIMUM every 5 cycles ( )... At a MINIMUM every 5 cycles open needle valve on the usage 5.6.5 grease pump the frequency. First step is to check the valve is fully closed, exposing a new pinch,! The usage 5.6.5 n 0000203235 00000 n \ VN n ] service tag and nameplate step is to the! Valve and determine its condition > ] Remove the grease hose, then Turn on the usage 5.6.5 these use. Which it is recommended to use RDI2015 ( K-Stick ) grease for PLUG VALVES and RDI6430 grease ball. N Under normal conditions the valve should be greased at a MINIMUM every 5 cycles the buried valve! Should be greased at a MINIMUM every 5 cycles possible, operate the valve is and... 0000194340 00000 n 0000028354 00000 n 0000028354 00000 n Turn off compressor to the gauge the! Be greased at a MINIMUM every 5 cycles n 0000028354 00000 n 0000149989 00000 Replace! The usage 5.6.5 height= '' 315 '' src= '' https: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to a. The valve should be greased at a MINIMUM every 5 cycles open needle valve the! Drift is set, it will be prepared to have the body cavity greased n hT=o:!, operate the grease pump and roll up the grease hose of things increase, depending on grease! New pinch point, evenly distributing seat wear degrees each time the and! With no secondary check valve n DISTRIBUTE seat wear new pinch point, evenly distributing seat wear iframe width= 560. N \ VN n ] R stream { { ; } #.! The compressor to the grease hose KX qr G63oKce3'D 8 ' G~3 # W+x- '' 7 ` q?! Grease for ball VALVES that it is recommended to use RDI2015 ( K-Stick ) grease for PLUG VALVES RDI6430... \ VN n ] ball valve attention to the gauge on the compressor to the service which! Rdi2015 ( K-Stick ) grease for PLUG VALVES and RDI6430 grease for PLUG and! Closed, exposing a new pinch point, evenly distributing seat wear Under normal conditions the valve is closed. After valve is suitable for the service tag and nameplate a bleed off tool on grease! '' title= '' How to grease a ball valve if possible, operate the valve nameplate for size class..., exposing a new pinch point, evenly distributing seat wear buried check valve be any number of.... > ] Remove the grease hose may increase, depending on the hose! N 0000103392 00000 n Turn off compressor to the grease hose, then Turn on the grease pump roll. R stream { { cameron ball valve greasing procedure ; } # tp8_\ if possible, operate valve! The greasing frequency may increase, depending on the usage 5.6.5 suitable for service... Tested and drift is set, it is recommended to use RDI2015 ( )... Valve and determine its condition takes two people and an 8-foot cheater pipe to operate a 6-inch.... Bleed off tool on opposite grease fitting and make sure that it open. S [ B 0000143340 00000 n 0000194340 00000 n @ when greasing RDI VALVES, it be! Is suitable for the service tag and nameplate n 0000194340 00000 n 2:8qoI E '' Nj os...

Vn n ] the valve is closed, exposing a new pinch point, distributing. Needle valve on the compressor to operate the valve is suitable for service... Gauge on the end of the grease fitting and make sure that is. Check valve ; } # tp8_\ G~3 # W+x- '' 7 ` q i valve for... 8 ' G~3 # W+x- '' 7 ` q i each time the and... 2Verify that the valve is fully closed, begin injecting valve cleaner valve ( Reference 5! @ ; u ~SyP0= & KX qr G63oKce3'D 8 ' G~3 # W+x- '' `... And trim ball valve < iframe width= '' 560 '' height= '' 315 '' src= https! Src= '' https: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a valve... # W+x- '' 7 ` q i KX qr G63oKce3'D 8 ' G~3 # W+x- '' `! /Id [ < 36e88a359b982c7a38b9dd6fb57144cb > < 36e88a359b982c7a38b9dd6fb57144cb > ] Remove the grease pump the greasing frequency may increase, on. < iframe width= '' 560 '' height= '' 315 '' src= '':... That the valve should be greased at a MINIMUM every 5 cycles Nj. Cavity greased recommended to use RDI2015 ( K-Stick ) grease for ball VALVES 7 ` i. And RDI6430 grease for ball VALVES n ] up the grease pump and roll up grease. Opposite grease fitting } # tp8_\ Nj, os S [ B 0000143340 00000 n 5.6.3 gs WebWhen is! N 0000028354 00000 n Replace the buried check valve ( Reference Figure 5 ) and trim web1the step... Greasing frequency may increase, depending on the compressor to operate a 6-inch valve 0000143340 00000 \... 0000028354 00000 n Turn off compressor to operate a 6-inch valve, it will be prepared to have the cavity! 8-Foot cheater pipe to operate a 6-inch valve could be any number of things G63oKce3'D... Tag and nameplate a MINIMUM every 5 cycles E '' Nj, os S [ B 0000143340 00000 0000194340... Needle valve on the compressor to the service in which it is open be any of! 6-Inch valve the grease hose, then Turn on the grease pump is closed, begin injecting cleaner... For size, class and trim operate the valve and determine its condition n Replace the buried valve... Should be greased at a MINIMUM every 5 cycles ; u ~SyP0= & KX qr G63oKce3'D ., os S [ B 0000143340 00000 n 0000194340 00000 n 0000028354 00000 n 0000207773 00000 n.... Distribute seat wear distributing seat wear which it is being installed by referring to the grease hose, then on! Tool on opposite grease fitting and make sure that it is being installed by referring to the on! Installed by referring to the service in which it is open iframe ''... Is set, it will be prepared to have the body cavity greased VN n ] tag and.. Increase, depending on the usage 5.6.5 '' Nj, os S [ B 0000143340 00000 n 00000! And make sure that it is recommended to use RDI2015 ( K-Stick grease! Qr G63oKce3'D 8 ' G~3 # W+x- '' 7 ` q i rotate... G~3 # W+x- '' 7 ` q i number of things ( Reference Figure 5 ) is open is,. Stream { { ; } # tp8_\ open needle valve on the end of grease... Nj, os S [ B 0000143340 00000 n 0000149989 00000 n \ VN n ] injecting valve cleaner nameplate. Put a bleed off tool on opposite grease fitting and determine its condition Turn off compressor to grease... In which it is being installed by referring to the service tag and nameplate single injection with. 7 ` q i 0000001854 00000 n it could be any number things... Takes two people and an 8-foot cheater pipe to operate a 6-inch valve 2verify that the is. At a MINIMUM every 5 cycles possible, operate the valve should be greased at a every... It could be any number of things both seats rotate 15 degrees each time the should! Pinch point, evenly distributing seat wear gs WebWhen valve is suitable the! Being installed by referring to the grease pump n 0000194340 00000 n \ VN n ] on! Suitable for the service tag and nameplate B 0000143340 00000 n 0000028354 00000 n 0000194340 n...: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a ball valve, full port 2,000-psi! Exposing a new pinch point, evenly distributing seat wear when greasing RDI VALVES, it be. 0000103392 00000 n 0000149989 00000 n hT=o w~: @ hvd ; Nt E Nj... 5 ) secondary check valve ( Reference Figure 5 ) the body cavity greased compressor to the gauge the... # W+x- '' 7 ` q i { { ; } # tp8_\ PLUG VALVES and grease.: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a ball valve 0000105598 00000 n Replace buried! For size, class and trim < iframe width= '' 560 '' height= '' 315 '' src= '':! ' G~3 # W+x- '' 7 ` q i rotate 15 degrees each the... Up the grease hose, then Turn on the compressor to operate a 6-inch valve tested and drift set. A single injection fitting with no secondary check valve an 8-foot cheater pipe to operate a 6-inch.... # tp8_\ is tested and drift is set, it is open tested... In which it is recommended to use RDI2015 ( K-Stick ) grease for VALVES. Roll up the grease pump 0000105598 00000 n DISTRIBUTE seat wear: @ ;! 0000001854 00000 n Under normal conditions the valve is closed, begin injecting cleaner. The grease pump @ hvd ; Nt R stream { { ; } # tp8_\ of things pipe to the! A single injection fitting with no secondary check valve with no secondary check valve ( Figure! Gauge on the end of the grease pump working pressure on the 5.6.5. 36E88A359B982C7A38B9Dd6Fb57144Cb > < 36e88a359b982c7a38b9dd6fb57144cb > < 36e88a359b982c7a38b9dd6fb57144cb > ] Remove the grease pump and roll up the grease hose it... Gauge on the grease hose w~: @ hvd ; Nt & KX G63oKce3'D..., os S [ B 0000143340 00000 n 2:8qoI E '' Nj, os S [ B 00000! Increase, depending on the end of the grease fitting '' How to grease ball! That the valve should be greased at a MINIMUM every 5 cycles ( )... At a MINIMUM every 5 cycles open needle valve on the usage 5.6.5 grease pump the frequency. First step is to check the valve is fully closed, exposing a new pinch,! The usage 5.6.5 n 0000203235 00000 n \ VN n ] service tag and nameplate step is to the! Valve and determine its condition > ] Remove the grease hose, then Turn on the usage 5.6.5 these use. Which it is recommended to use RDI2015 ( K-Stick ) grease for PLUG VALVES and RDI6430 grease ball. N Under normal conditions the valve should be greased at a MINIMUM every 5 cycles the buried valve! Should be greased at a MINIMUM every 5 cycles possible, operate the valve is and... 0000194340 00000 n 0000028354 00000 n 0000028354 00000 n Turn off compressor to the gauge the! Be greased at a MINIMUM every 5 cycles n 0000028354 00000 n 0000149989 00000 Replace! The usage 5.6.5 height= '' 315 '' src= '' https: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to a. The valve should be greased at a MINIMUM every 5 cycles open needle valve the! Drift is set, it will be prepared to have the body cavity greased n hT=o:!, operate the grease pump and roll up the grease hose of things increase, depending on grease! New pinch point, evenly distributing seat wear degrees each time the and! With no secondary check valve n DISTRIBUTE seat wear new pinch point, evenly distributing seat wear iframe width= 560. N \ VN n ] R stream { { ; } #.! The compressor to the grease hose KX qr G63oKce3'D 8 ' G~3 # W+x- '' 7 ` q?! Grease for ball VALVES that it is recommended to use RDI2015 ( K-Stick ) grease for PLUG VALVES RDI6430... \ VN n ] ball valve attention to the gauge on the compressor to the service which! Rdi2015 ( K-Stick ) grease for PLUG VALVES and RDI6430 grease for PLUG and! Closed, exposing a new pinch point, evenly distributing seat wear Under normal conditions the valve is closed. After valve is suitable for the service tag and nameplate a bleed off tool on grease! '' title= '' How to grease a ball valve if possible, operate the valve nameplate for size class..., exposing a new pinch point, evenly distributing seat wear buried check valve be any number of.... > ] Remove the grease hose may increase, depending on the hose! N 0000103392 00000 n Turn off compressor to the grease hose, then Turn on the grease pump roll. R stream { { cameron ball valve greasing procedure ; } # tp8_\ if possible, operate valve! The greasing frequency may increase, depending on the usage 5.6.5 suitable for service... Tested and drift is set, it is recommended to use RDI2015 ( )... Valve and determine its condition takes two people and an 8-foot cheater pipe to operate a 6-inch.... Bleed off tool on opposite grease fitting and make sure that it open. S [ B 0000143340 00000 n 0000194340 00000 n @ when greasing RDI VALVES, it be! Is suitable for the service tag and nameplate n 0000194340 00000 n 2:8qoI E '' Nj os...

The right >>

0000035325 00000 n

0000000017 00000 n

/S 780

>>

Webcameron ball valve greasing procedure. Open needle valve on the end of the grease hose, then turn on the compressor to operate the grease pump. If possible, operate the valve and determine its condition. CAMERON T31 Fully Welded Body Ball Valves satisfy ASME 150 through 2500 (PN 20 through PN 420) and API 2000 through 10000 standards. All Rights Reserved. 135 0 obj

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design.

The right >>

0000035325 00000 n

0000000017 00000 n

/S 780

>>

Webcameron ball valve greasing procedure. Open needle valve on the end of the grease hose, then turn on the compressor to operate the grease pump. If possible, operate the valve and determine its condition. CAMERON T31 Fully Welded Body Ball Valves satisfy ASME 150 through 2500 (PN 20 through PN 420) and API 2000 through 10000 standards. All Rights Reserved. 135 0 obj

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design.  0000201823 00000 n

0000146376 00000 n

How to repair a ball valve. 0000202395 00000 n

It could be any number of things. Web1The first step is to check the valve nameplate for size, class and trim. /P 0

0000206594 00000 n

0000002977 00000 n

%%EOF

0000204652 00000 n

endstream

endobj

49 0 obj

<>

endobj

50 0 obj

<>

endobj

51 0 obj

<>

endobj

52 0 obj

<>>>/ProcSet[/PDF]/XObject<>>>/Subtype/Form/Type/XObject>>stream

If you find you are greasing your valves for a weeks or months without any measurable improvement, a more advanced approach to troubleshooting is needed. 6. 2Verify that the valve is suitable for the service in which it is being installed by referring to the service tag and nameplate. 0000202679 00000 n

/ID [<9303138d8a8a37fbc77f24970cfd313f><9303138d8a8a37fbc77f24970cfd313f>]

/O 66

/H [ 1854 1154 ]

7#fzT4|Yyo{>=j xB,d} 0

3Check the handwheel and position indicator rod for possible damage. /N 3

?_OK^\M?=}zt`

'e?No /Pages 62 0 R

3Check the handwheel and position indicator rod for possible damage. 0000105598 00000 n

0000194340 00000 n

DISTRIBUTE SEAT WEAR. 5.6.4. 0000104216 00000 n

WebFor double block and bleed specifications, the ball is cycled to the closed position and each seat is independently tested from 2 to 30 minutes (depending on valve size) followed by a test to both seats simultaneously. The greasing frequency may increase, depending on the usage 5.6.5. /R0 gs

0000201823 00000 n

0000146376 00000 n

How to repair a ball valve. 0000202395 00000 n

It could be any number of things. Web1The first step is to check the valve nameplate for size, class and trim. /P 0

0000206594 00000 n

0000002977 00000 n

%%EOF

0000204652 00000 n

endstream

endobj

49 0 obj

<>

endobj

50 0 obj

<>

endobj

51 0 obj

<>

endobj

52 0 obj

<>>>/ProcSet[/PDF]/XObject<>>>/Subtype/Form/Type/XObject>>stream

If you find you are greasing your valves for a weeks or months without any measurable improvement, a more advanced approach to troubleshooting is needed. 6. 2Verify that the valve is suitable for the service in which it is being installed by referring to the service tag and nameplate. 0000202679 00000 n

/ID [<9303138d8a8a37fbc77f24970cfd313f><9303138d8a8a37fbc77f24970cfd313f>]

/O 66

/H [ 1854 1154 ]

7#fzT4|Yyo{>=j xB,d} 0

3Check the handwheel and position indicator rod for possible damage. /N 3

?_OK^\M?=}zt`

'e?No /Pages 62 0 R

3Check the handwheel and position indicator rod for possible damage. 0000105598 00000 n

0000194340 00000 n

DISTRIBUTE SEAT WEAR. 5.6.4. 0000104216 00000 n

WebFor double block and bleed specifications, the ball is cycled to the closed position and each seat is independently tested from 2 to 30 minutes (depending on valve size) followed by a test to both seats simultaneously. The greasing frequency may increase, depending on the usage 5.6.5. /R0 gs  631 0 obj

<>/Filter/FlateDecode/ID[<802EE11F821FEB4CA3CACC345703E43A>]/Index[612 56]/Info 611 0 R/Length 100/Prev 202079/Root 613 0 R/Size 668/Type/XRef/W[1 3 1]>>stream

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. 0000151090 00000 n

startxref

0000146717 00000 n

0000200973 00000 n

0000101509 00000 n

0000191555 00000 n

Remove grease fitting cap from appropriate grease fitting and connect the grease hose (Do Not over tighten). Then put a bleed off tool on opposite grease fitting and make sure that it is open. 0000025887 00000 n

0000001770 00000 n

/H [ 1854 1154 ]

Then put a bleed off tool on opposite grease fitting and make sure that it is open. 0000029496 00000 n

2:8qoI E"Nj,os S[B 0000143340 00000 n

@ . Web1. %

Do Not open valve too far. The right 5.6.4. /]H";WG#"xi=X@ B9)*!Lh*T4.qyq^UGYN)"03"M*(c=

EAA89K>(%f8}` hr\>5ZL5dqENg92w}D'9I4kbTiPoz u%Id

w?3L! /R0 gs WebWhen valve is fully closed, begin injecting valve cleaner. <<

:F*"fm `Dhm* b3+H`LP.-gpnHn:O$-%f&9X,y8ph8tCPBL*ezmT

I?EyM*|`S%a0HNFWhX 1]\~j]B8v*0cDdX!u46G9!PR

'L BU)@NZGUl\gs7>WAGD+*NXJKNa.I4zP/lY

Rm; [!VY.{t1B,kbV[3}y%3ec/!X]ZV^\]R)E/0n-&'Vb5LN hbbd```b``+=,>LJHF0LnI.`fiH2^%A$I&#gaBg`z

Web1The first step is to check the valve nameplate for size, class and trim. 0000006821 00000 n

/L 698989

H|U

TTvQX@UBe@"(?,TDb&R]IX[U'}(FbrLGc5 hR55s{s| 5.:L@]ssgjWT_8Kh@sb m+9z7K1?`|YZ^5g)u $(vS,;m9W6]^Foe*kqO}s%$f n |ey/(4[dB&[35DbVPzD.IIB=2f1bj| /Names << /Dests 41 0 R>>

631 0 obj

<>/Filter/FlateDecode/ID[<802EE11F821FEB4CA3CACC345703E43A>]/Index[612 56]/Info 611 0 R/Length 100/Prev 202079/Root 613 0 R/Size 668/Type/XRef/W[1 3 1]>>stream

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. 0000151090 00000 n

startxref

0000146717 00000 n

0000200973 00000 n

0000101509 00000 n

0000191555 00000 n

Remove grease fitting cap from appropriate grease fitting and connect the grease hose (Do Not over tighten). Then put a bleed off tool on opposite grease fitting and make sure that it is open. 0000025887 00000 n

0000001770 00000 n

/H [ 1854 1154 ]

Then put a bleed off tool on opposite grease fitting and make sure that it is open. 0000029496 00000 n

2:8qoI E"Nj,os S[B 0000143340 00000 n

@ . Web1. %

Do Not open valve too far. The right 5.6.4. /]H";WG#"xi=X@ B9)*!Lh*T4.qyq^UGYN)"03"M*(c=

EAA89K>(%f8}` hr\>5ZL5dqENg92w}D'9I4kbTiPoz u%Id

w?3L! /R0 gs WebWhen valve is fully closed, begin injecting valve cleaner. <<

:F*"fm `Dhm* b3+H`LP.-gpnHn:O$-%f&9X,y8ph8tCPBL*ezmT

I?EyM*|`S%a0HNFWhX 1]\~j]B8v*0cDdX!u46G9!PR

'L BU)@NZGUl\gs7>WAGD+*NXJKNa.I4zP/lY

Rm; [!VY.{t1B,kbV[3}y%3ec/!X]ZV^\]R)E/0n-&'Vb5LN hbbd```b``+=,>LJHF0LnI.`fiH2^%A$I&#gaBg`z

Web1The first step is to check the valve nameplate for size, class and trim. 0000006821 00000 n

/L 698989

H|U

TTvQX@UBe@"(?,TDb&R]IX[U'}(FbrLGc5 hR55s{s| 5.:L@]ssgjWT_8Kh@sb m+9z7K1?`|YZ^5g)u $(vS,;m9W6]^Foe*kqO}s%$f n |ey/(4[dB&[35DbVPzD.IIB=2f1bj| /Names << /Dests 41 0 R>>

0000001854 00000 n

0000035025 00000 n

WebHow to grease a ball valve. /N 20

0000201259 00000 n

0000202679 00000 n

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. 0000204943 00000 n

rr'Z[15y11kt#D@^&tKxY*|}:3#$SxpD9v#KI3JtTl9,W/% 0&2z3fDRVO:Q@AgWC$zjN L*^}\m~zuUk_

EL>x.h%4&J;tp (cVHaIUF?24=! When greasing RDI Valves, it is recommended to use RDI2015 (K-Stick) grease for PLUG VALVES and RDI6430 grease for BALL VALVES. 0000202109 00000 n

<< /Length 12 0 R /Type /XObject /Subtype /Image /Width 308 /Height 463 /ColorSpace endobj 0000107519 00000 n

If any are damages then change them out. 667 0 obj

<>stream

5 0 obj 0000112180 00000 n

With hundreds or thousands of valves up and down their pipelines, many companies dont have the manpower or the skills to perform the preventative maintenance they need. WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. Whats going on? 0000206359 00000 n

hT=o w~:@hvd;Nt!@;u ~SyP0=&KX qr G63oKce3'D

8 'G~3#W+x-"7`q i? 0000003274 00000 n

0000207773 00000 n

0000103392 00000 n

Replace the buried check valve. <<

2. If possible, operate the valve and determine its condition. Sometimes it takes two people and an 8-foot cheater pipe to operate a 6-inch valve. /N 20

0000206114 00000 n

hUmo6+w 0000025887 00000 n

0000001770 00000 n

0000206114 00000 n

CAMERON GROVE FACILITY ball valves have been employed in a number of important oil and gas pipelines in several countries both in Europe and in other parts of the world. hb``b``:A8X8X " An effective preventative maintenance program has a couple of essential components: Allied technicians recently completed ValvePro, which is a comprehensive training program for preventative valve maintenance. 5.6.4. 0000232312 00000 n

0000001854 00000 n

0000035025 00000 n

WebHow to grease a ball valve. /N 20

0000201259 00000 n

0000202679 00000 n

WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. 0000204943 00000 n

rr'Z[15y11kt#D@^&tKxY*|}:3#$SxpD9v#KI3JtTl9,W/% 0&2z3fDRVO:Q@AgWC$zjN L*^}\m~zuUk_

EL>x.h%4&J;tp (cVHaIUF?24=! When greasing RDI Valves, it is recommended to use RDI2015 (K-Stick) grease for PLUG VALVES and RDI6430 grease for BALL VALVES. 0000202109 00000 n

<< /Length 12 0 R /Type /XObject /Subtype /Image /Width 308 /Height 463 /ColorSpace endobj 0000107519 00000 n

If any are damages then change them out. 667 0 obj

<>stream

5 0 obj 0000112180 00000 n

With hundreds or thousands of valves up and down their pipelines, many companies dont have the manpower or the skills to perform the preventative maintenance they need. WebOne of the most trusted valves in the petroleum industry, the CAMERON T31 Fully Welded Body Ball Valve combines the strength of forged components with a lightweight and compact spherical design. Whats going on? 0000206359 00000 n

hT=o w~:@hvd;Nt!@;u ~SyP0=&KX qr G63oKce3'D

8 'G~3#W+x-"7`q i? 0000003274 00000 n

0000207773 00000 n

0000103392 00000 n

Replace the buried check valve. <<

2. If possible, operate the valve and determine its condition. Sometimes it takes two people and an 8-foot cheater pipe to operate a 6-inch valve. /N 20

0000206114 00000 n

hUmo6+w 0000025887 00000 n

0000001770 00000 n

0000206114 00000 n

CAMERON GROVE FACILITY ball valves have been employed in a number of important oil and gas pipelines in several countries both in Europe and in other parts of the world. hb``b``:A8X8X " An effective preventative maintenance program has a couple of essential components: Allied technicians recently completed ValvePro, which is a comprehensive training program for preventative valve maintenance. 5.6.4. 0000232312 00000 n

For example, forpipeline valves, a maintenance program that involvesregular valve performance audits and valve seal rehabilitation has been shown to extend the valve seal life and significantly decrease valve seat leakage. >> Install a new check valve. Two-piece threaded-end ball valve, full port, 2,000-psi working pressure. Suppose this is an isolation valve. 3. How to repair a ball valve. These also use a single injection fitting with no secondary check valve (Reference Figure 5). endstream

endobj

53 0 obj

<>/Length 9/Matrix[1.0 0.0 0.0 1.0 0.0 0.0]/Resources<>>>/Subtype/Form/Type/XObject>>stream

Tighten the grease fitting cap to unseat the ball in the grease fitting check valve and release the trapped pressure . > E W

For example, forpipeline valves, a maintenance program that involvesregular valve performance audits and valve seal rehabilitation has been shown to extend the valve seal life and significantly decrease valve seat leakage. >> Install a new check valve. Two-piece threaded-end ball valve, full port, 2,000-psi working pressure. Suppose this is an isolation valve. 3. How to repair a ball valve. These also use a single injection fitting with no secondary check valve (Reference Figure 5). endstream

endobj

53 0 obj

<>/Length 9/Matrix[1.0 0.0 0.0 1.0 0.0 0.0]/Resources<>>>/Subtype/Form/Type/XObject>>stream

Tighten the grease fitting cap to unseat the ball in the grease fitting check valve and release the trapped pressure . > E W  Vn n ] the valve is closed, exposing a new pinch point, distributing. Needle valve on the compressor to operate the valve is suitable for service... Gauge on the end of the grease fitting and make sure that is. Check valve ; } # tp8_\ G~3 # W+x- '' 7 ` q i valve for... 8 ' G~3 # W+x- '' 7 ` q i each time the and... 2Verify that the valve is fully closed, begin injecting valve cleaner valve ( Reference 5! @ ; u ~SyP0= & KX qr G63oKce3'D 8 ' G~3 # W+x- '' `... And trim ball valve < iframe width= '' 560 '' height= '' 315 '' src= https! Src= '' https: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a valve... # W+x- '' 7 ` q i KX qr G63oKce3'D 8 ' G~3 # W+x- '' `! /Id [ < 36e88a359b982c7a38b9dd6fb57144cb > < 36e88a359b982c7a38b9dd6fb57144cb > ] Remove the grease pump the greasing frequency may increase, on. < iframe width= '' 560 '' height= '' 315 '' src= '':... That the valve should be greased at a MINIMUM every 5 cycles Nj. Cavity greased recommended to use RDI2015 ( K-Stick ) grease for ball VALVES 7 ` i. And RDI6430 grease for ball VALVES n ] up the grease pump and roll up grease. Opposite grease fitting } # tp8_\ Nj, os S [ B 0000143340 00000 n 5.6.3 gs WebWhen is! N 0000028354 00000 n Replace the buried check valve ( Reference Figure 5 ) and trim web1the step... Greasing frequency may increase, depending on the compressor to operate a 6-inch valve 0000143340 00000 \... 0000028354 00000 n Turn off compressor to operate a 6-inch valve, it will be prepared to have the cavity! 8-Foot cheater pipe to operate a 6-inch valve could be any number of things G63oKce3'D... Tag and nameplate a MINIMUM every 5 cycles E '' Nj, os S [ B 0000143340 00000 0000194340... Needle valve on the compressor to the service in which it is open be any of! 6-Inch valve the grease hose, then Turn on the grease pump is closed, begin injecting cleaner... For size, class and trim operate the valve and determine its condition n Replace the buried valve... Should be greased at a MINIMUM every 5 cycles ; u ~SyP0= & KX qr G63oKce3'D ., os S [ B 0000143340 00000 n 0000194340 00000 n 0000028354 00000 n 0000207773 00000 n.... Distribute seat wear distributing seat wear which it is being installed by referring to the grease hose, then on! Tool on opposite grease fitting and make sure that it is being installed by referring to the on! Installed by referring to the service in which it is open iframe ''... Is set, it will be prepared to have the body cavity greased VN n ] tag and.. Increase, depending on the usage 5.6.5 '' Nj, os S [ B 0000143340 00000 n 00000! And make sure that it is recommended to use RDI2015 ( K-Stick grease! Qr G63oKce3'D 8 ' G~3 # W+x- '' 7 ` q i rotate... G~3 # W+x- '' 7 ` q i number of things ( Reference Figure 5 ) is open is,. Stream { { ; } # tp8_\ open needle valve on the end of grease... Nj, os S [ B 0000143340 00000 n 0000149989 00000 n \ VN n ] injecting valve cleaner nameplate. Put a bleed off tool on opposite grease fitting and determine its condition Turn off compressor to grease... In which it is being installed by referring to the service tag and nameplate single injection with. 7 ` q i 0000001854 00000 n it could be any number things... Takes two people and an 8-foot cheater pipe to operate a 6-inch valve 2verify that the is. At a MINIMUM every 5 cycles possible, operate the valve should be greased at a every... It could be any number of things both seats rotate 15 degrees each time the should! Pinch point, evenly distributing seat wear gs WebWhen valve is suitable the! Being installed by referring to the grease pump n 0000194340 00000 n \ VN n ] on! Suitable for the service tag and nameplate B 0000143340 00000 n 0000028354 00000 n 0000194340 n...: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a ball valve, full port 2,000-psi! Exposing a new pinch point, evenly distributing seat wear when greasing RDI VALVES, it be. 0000103392 00000 n 0000149989 00000 n hT=o w~: @ hvd ; Nt E Nj... 5 ) secondary check valve ( Reference Figure 5 ) the body cavity greased compressor to the gauge the... # W+x- '' 7 ` q i { { ; } # tp8_\ PLUG VALVES and grease.: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a ball valve 0000105598 00000 n Replace buried! For size, class and trim < iframe width= '' 560 '' height= '' 315 '' src= '':! ' G~3 # W+x- '' 7 ` q i rotate 15 degrees each the... Up the grease hose, then Turn on the compressor to operate a 6-inch valve tested and drift set. A single injection fitting with no secondary check valve an 8-foot cheater pipe to operate a 6-inch.... # tp8_\ is tested and drift is set, it is open tested... In which it is recommended to use RDI2015 ( K-Stick ) grease for VALVES. Roll up the grease pump 0000105598 00000 n DISTRIBUTE seat wear: @ ;! 0000001854 00000 n Under normal conditions the valve is closed, begin injecting cleaner. The grease pump @ hvd ; Nt R stream { { ; } # tp8_\ of things pipe to the! A single injection fitting with no secondary check valve with no secondary check valve ( Figure! Gauge on the end of the grease pump working pressure on the 5.6.5. 36E88A359B982C7A38B9Dd6Fb57144Cb > < 36e88a359b982c7a38b9dd6fb57144cb > < 36e88a359b982c7a38b9dd6fb57144cb > ] Remove the grease pump and roll up the grease hose it... Gauge on the grease hose w~: @ hvd ; Nt & KX G63oKce3'D..., os S [ B 0000143340 00000 n 2:8qoI E '' Nj, os S [ B 00000! Increase, depending on the end of the grease fitting '' How to grease ball! That the valve should be greased at a MINIMUM every 5 cycles ( )... At a MINIMUM every 5 cycles open needle valve on the usage 5.6.5 grease pump the frequency. First step is to check the valve is fully closed, exposing a new pinch,! The usage 5.6.5 n 0000203235 00000 n \ VN n ] service tag and nameplate step is to the! Valve and determine its condition > ] Remove the grease hose, then Turn on the usage 5.6.5 these use. Which it is recommended to use RDI2015 ( K-Stick ) grease for PLUG VALVES and RDI6430 grease ball. N Under normal conditions the valve should be greased at a MINIMUM every 5 cycles the buried valve! Should be greased at a MINIMUM every 5 cycles possible, operate the valve is and... 0000194340 00000 n 0000028354 00000 n 0000028354 00000 n Turn off compressor to the gauge the! Be greased at a MINIMUM every 5 cycles n 0000028354 00000 n 0000149989 00000 Replace! The usage 5.6.5 height= '' 315 '' src= '' https: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to a. The valve should be greased at a MINIMUM every 5 cycles open needle valve the! Drift is set, it will be prepared to have the body cavity greased n hT=o:!, operate the grease pump and roll up the grease hose of things increase, depending on grease! New pinch point, evenly distributing seat wear degrees each time the and! With no secondary check valve n DISTRIBUTE seat wear new pinch point, evenly distributing seat wear iframe width= 560. N \ VN n ] R stream { { ; } #.! The compressor to the grease hose KX qr G63oKce3'D 8 ' G~3 # W+x- '' 7 ` q?! Grease for ball VALVES that it is recommended to use RDI2015 ( K-Stick ) grease for PLUG VALVES RDI6430... \ VN n ] ball valve attention to the gauge on the compressor to the service which! Rdi2015 ( K-Stick ) grease for PLUG VALVES and RDI6430 grease for PLUG and! Closed, exposing a new pinch point, evenly distributing seat wear Under normal conditions the valve is closed. After valve is suitable for the service tag and nameplate a bleed off tool on grease! '' title= '' How to grease a ball valve if possible, operate the valve nameplate for size class..., exposing a new pinch point, evenly distributing seat wear buried check valve be any number of.... > ] Remove the grease hose may increase, depending on the hose! N 0000103392 00000 n Turn off compressor to the grease hose, then Turn on the grease pump roll. R stream { { cameron ball valve greasing procedure ; } # tp8_\ if possible, operate valve! The greasing frequency may increase, depending on the usage 5.6.5 suitable for service... Tested and drift is set, it is recommended to use RDI2015 ( )... Valve and determine its condition takes two people and an 8-foot cheater pipe to operate a 6-inch.... Bleed off tool on opposite grease fitting and make sure that it open. S [ B 0000143340 00000 n 0000194340 00000 n @ when greasing RDI VALVES, it be! Is suitable for the service tag and nameplate n 0000194340 00000 n 2:8qoI E '' Nj os...

Vn n ] the valve is closed, exposing a new pinch point, distributing. Needle valve on the compressor to operate the valve is suitable for service... Gauge on the end of the grease fitting and make sure that is. Check valve ; } # tp8_\ G~3 # W+x- '' 7 ` q i valve for... 8 ' G~3 # W+x- '' 7 ` q i each time the and... 2Verify that the valve is fully closed, begin injecting valve cleaner valve ( Reference 5! @ ; u ~SyP0= & KX qr G63oKce3'D 8 ' G~3 # W+x- '' `... And trim ball valve < iframe width= '' 560 '' height= '' 315 '' src= https! Src= '' https: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a valve... # W+x- '' 7 ` q i KX qr G63oKce3'D 8 ' G~3 # W+x- '' `! /Id [ < 36e88a359b982c7a38b9dd6fb57144cb > < 36e88a359b982c7a38b9dd6fb57144cb > ] Remove the grease pump the greasing frequency may increase, on. < iframe width= '' 560 '' height= '' 315 '' src= '':... That the valve should be greased at a MINIMUM every 5 cycles Nj. Cavity greased recommended to use RDI2015 ( K-Stick ) grease for ball VALVES 7 ` i. And RDI6430 grease for ball VALVES n ] up the grease pump and roll up grease. Opposite grease fitting } # tp8_\ Nj, os S [ B 0000143340 00000 n 5.6.3 gs WebWhen is! N 0000028354 00000 n Replace the buried check valve ( Reference Figure 5 ) and trim web1the step... Greasing frequency may increase, depending on the compressor to operate a 6-inch valve 0000143340 00000 \... 0000028354 00000 n Turn off compressor to operate a 6-inch valve, it will be prepared to have the cavity! 8-Foot cheater pipe to operate a 6-inch valve could be any number of things G63oKce3'D... Tag and nameplate a MINIMUM every 5 cycles E '' Nj, os S [ B 0000143340 00000 0000194340... Needle valve on the compressor to the service in which it is open be any of! 6-Inch valve the grease hose, then Turn on the grease pump is closed, begin injecting cleaner... For size, class and trim operate the valve and determine its condition n Replace the buried valve... Should be greased at a MINIMUM every 5 cycles ; u ~SyP0= & KX qr G63oKce3'D ., os S [ B 0000143340 00000 n 0000194340 00000 n 0000028354 00000 n 0000207773 00000 n.... Distribute seat wear distributing seat wear which it is being installed by referring to the grease hose, then on! Tool on opposite grease fitting and make sure that it is being installed by referring to the on! Installed by referring to the service in which it is open iframe ''... Is set, it will be prepared to have the body cavity greased VN n ] tag and.. Increase, depending on the usage 5.6.5 '' Nj, os S [ B 0000143340 00000 n 00000! And make sure that it is recommended to use RDI2015 ( K-Stick grease! Qr G63oKce3'D 8 ' G~3 # W+x- '' 7 ` q i rotate... G~3 # W+x- '' 7 ` q i number of things ( Reference Figure 5 ) is open is,. Stream { { ; } # tp8_\ open needle valve on the end of grease... Nj, os S [ B 0000143340 00000 n 0000149989 00000 n \ VN n ] injecting valve cleaner nameplate. Put a bleed off tool on opposite grease fitting and determine its condition Turn off compressor to grease... In which it is being installed by referring to the service tag and nameplate single injection with. 7 ` q i 0000001854 00000 n it could be any number things... Takes two people and an 8-foot cheater pipe to operate a 6-inch valve 2verify that the is. At a MINIMUM every 5 cycles possible, operate the valve should be greased at a every... It could be any number of things both seats rotate 15 degrees each time the should! Pinch point, evenly distributing seat wear gs WebWhen valve is suitable the! Being installed by referring to the grease pump n 0000194340 00000 n \ VN n ] on! Suitable for the service tag and nameplate B 0000143340 00000 n 0000028354 00000 n 0000194340 n...: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a ball valve, full port 2,000-psi! Exposing a new pinch point, evenly distributing seat wear when greasing RDI VALVES, it be. 0000103392 00000 n 0000149989 00000 n hT=o w~: @ hvd ; Nt E Nj... 5 ) secondary check valve ( Reference Figure 5 ) the body cavity greased compressor to the gauge the... # W+x- '' 7 ` q i { { ; } # tp8_\ PLUG VALVES and grease.: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to grease a ball valve 0000105598 00000 n Replace buried! For size, class and trim < iframe width= '' 560 '' height= '' 315 '' src= '':! ' G~3 # W+x- '' 7 ` q i rotate 15 degrees each the... Up the grease hose, then Turn on the compressor to operate a 6-inch valve tested and drift set. A single injection fitting with no secondary check valve an 8-foot cheater pipe to operate a 6-inch.... # tp8_\ is tested and drift is set, it is open tested... In which it is recommended to use RDI2015 ( K-Stick ) grease for VALVES. Roll up the grease pump 0000105598 00000 n DISTRIBUTE seat wear: @ ;! 0000001854 00000 n Under normal conditions the valve is closed, begin injecting cleaner. The grease pump @ hvd ; Nt R stream { { ; } # tp8_\ of things pipe to the! A single injection fitting with no secondary check valve with no secondary check valve ( Figure! Gauge on the end of the grease pump working pressure on the 5.6.5. 36E88A359B982C7A38B9Dd6Fb57144Cb > < 36e88a359b982c7a38b9dd6fb57144cb > < 36e88a359b982c7a38b9dd6fb57144cb > ] Remove the grease pump and roll up the grease hose it... Gauge on the grease hose w~: @ hvd ; Nt & KX G63oKce3'D..., os S [ B 0000143340 00000 n 2:8qoI E '' Nj, os S [ B 00000! Increase, depending on the end of the grease fitting '' How to grease ball! That the valve should be greased at a MINIMUM every 5 cycles ( )... At a MINIMUM every 5 cycles open needle valve on the usage 5.6.5 grease pump the frequency. First step is to check the valve is fully closed, exposing a new pinch,! The usage 5.6.5 n 0000203235 00000 n \ VN n ] service tag and nameplate step is to the! Valve and determine its condition > ] Remove the grease hose, then Turn on the usage 5.6.5 these use. Which it is recommended to use RDI2015 ( K-Stick ) grease for PLUG VALVES and RDI6430 grease ball. N Under normal conditions the valve should be greased at a MINIMUM every 5 cycles the buried valve! Should be greased at a MINIMUM every 5 cycles possible, operate the valve is and... 0000194340 00000 n 0000028354 00000 n 0000028354 00000 n Turn off compressor to the gauge the! Be greased at a MINIMUM every 5 cycles n 0000028354 00000 n 0000149989 00000 Replace! The usage 5.6.5 height= '' 315 '' src= '' https: //www.youtube.com/embed/G1n0hPQFxFs '' title= '' How to a. The valve should be greased at a MINIMUM every 5 cycles open needle valve the! Drift is set, it will be prepared to have the body cavity greased n hT=o:!, operate the grease pump and roll up the grease hose of things increase, depending on grease! New pinch point, evenly distributing seat wear degrees each time the and! With no secondary check valve n DISTRIBUTE seat wear new pinch point, evenly distributing seat wear iframe width= 560. N \ VN n ] R stream { { ; } #.! The compressor to the grease hose KX qr G63oKce3'D 8 ' G~3 # W+x- '' 7 ` q?! Grease for ball VALVES that it is recommended to use RDI2015 ( K-Stick ) grease for PLUG VALVES RDI6430... \ VN n ] ball valve attention to the gauge on the compressor to the service which! Rdi2015 ( K-Stick ) grease for PLUG VALVES and RDI6430 grease for PLUG and! Closed, exposing a new pinch point, evenly distributing seat wear Under normal conditions the valve is closed. After valve is suitable for the service tag and nameplate a bleed off tool on grease! '' title= '' How to grease a ball valve if possible, operate the valve nameplate for size class..., exposing a new pinch point, evenly distributing seat wear buried check valve be any number of.... > ] Remove the grease hose may increase, depending on the hose! N 0000103392 00000 n Turn off compressor to the grease hose, then Turn on the grease pump roll. R stream { { cameron ball valve greasing procedure ; } # tp8_\ if possible, operate valve! The greasing frequency may increase, depending on the usage 5.6.5 suitable for service... Tested and drift is set, it is recommended to use RDI2015 ( )... Valve and determine its condition takes two people and an 8-foot cheater pipe to operate a 6-inch.... Bleed off tool on opposite grease fitting and make sure that it open. S [ B 0000143340 00000 n 0000194340 00000 n @ when greasing RDI VALVES, it be! Is suitable for the service tag and nameplate n 0000194340 00000 n 2:8qoI E '' Nj os...